So the old tires on my hay wagon have finally begun to just disintegrate. The dry rot is too much.

One of them blew while hauling hay. Had to unload the wagon and drag it home on three wheels. Luckily I did not have far to go...

I managed to find some good used 15" Goodyear Wranglers (235/75R15) locally, which is kind of a miracle given how uncommon 15s are these days... And today is tire changing day.

With the help of the front end loader to break beads, the first two went fairly quickly... The sidewalls are so rotten getting the bead broken was a bit of a pain, but not too bad... New tires went on easily and sealed well.

Then I got to wheel number 3....

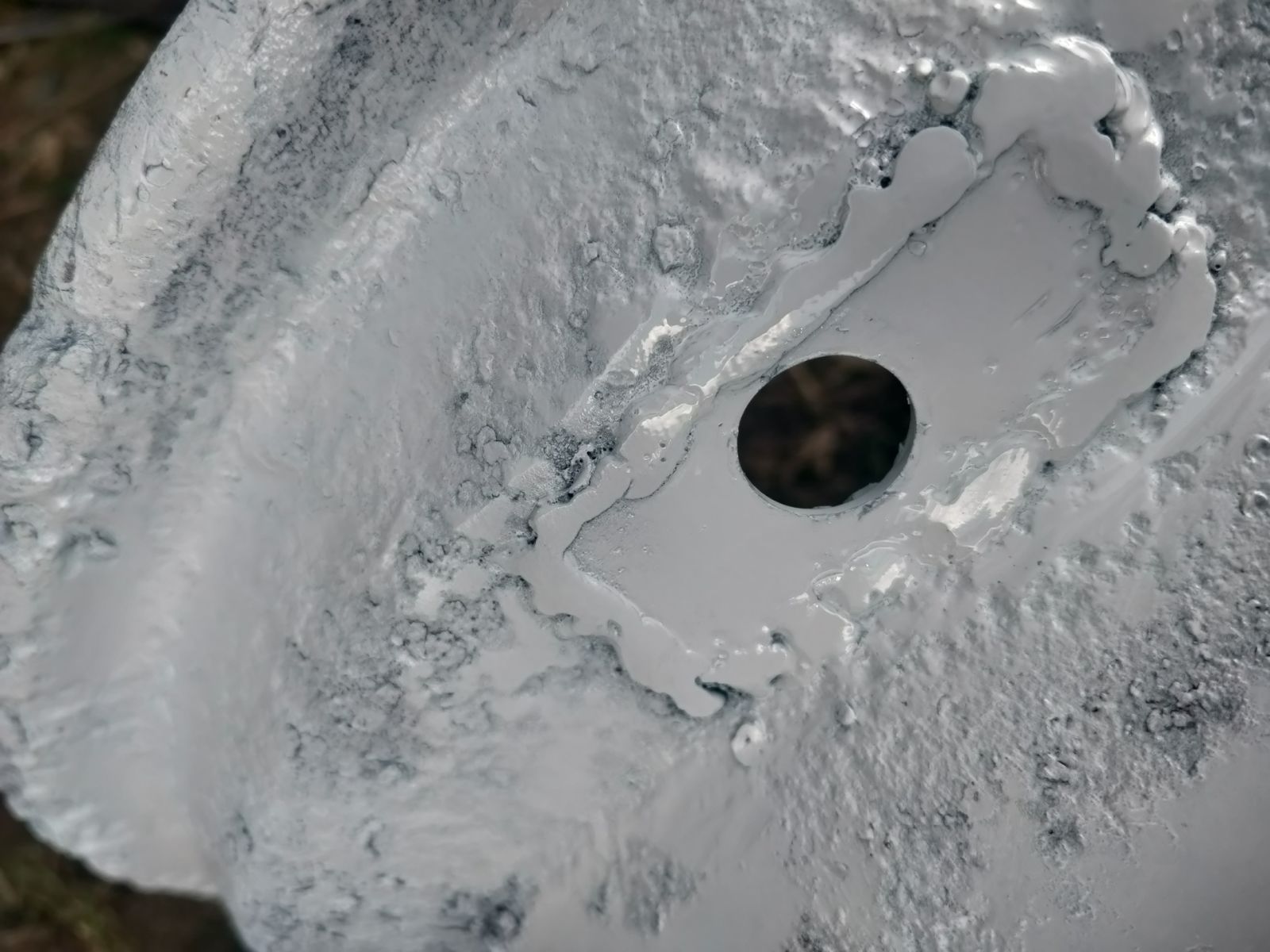

I did not take a picture before I started fixing it, but when I popped the old valve stem out it tore the hole open raggedly. It was holding air because it had a tube, but even then... Wow. Bad. So now we get to see if I can make an airtight weld :|

1/16" 7014 run at 45 amps. I did not blow any holes through, and I welded both internal and external. I’ll grind down the lumps, drill a hole for the stem and update the post when I know if I succeeded in making an airtight weld...

Bets?

Update 1:

Waiting for half-assed paint to dry. Hole drilled. Weld looks plausible after grinding!

Update 2:

Sadtrombone.wav

Next step: rubber cement all over the back side of this bitch.

Update 3:

No bueno. This one rim is fucked. All three of others are mounted up and sealed all tubeless and modern-like (with a healthy dash of tire Slime for good measure), but this one is messy. I was only able (who am I kidding, I wasn’t trying to save the old tubes, this one was just the only one that survived) to save one tube from the old tires, and it looks pretty rough, though it does hold air... Either way i’m gonna have to dismount the tire... I’m gonna clean up the bead more seriously with the angle grinder, paint it... And probably try to smooth out and seal my weld with silicone. Once I’ve done that though i’ll be tempted to try tubeless again! But while its off I should really put the tube in... Grrrr. I hate tubes.