There is something odd about taking a running project off the road. The R154 is stout by all means. With the achille’s heal addressed it supposedly can handle 800hp or so, but it has little problems like not wanting to go into reverse and being notchy as all hell. I got the short shifter to combat the fact that sometimes you would find a gate, but wouldn’t pull it far enough to actually engage the gear. By comparison the CD009 is super smooth, has 6 gears, can take a huge beating, and cheap. I had been collecting parts and making preparations for some bigger mods. A friend offered me use of their garage so I decided to start with the transmission swap.

These guys are HUGE. The R154 isn’t small by any measure, but the CD009 is massive.

First I started with the tranny mods.

The R154 is about 28 inches long I think 26 to the shifter. The CD009 is 28 inches long, but something like 34.5 inches to the shifter. I had a bit of a reach for the R154, but I didn’t think I could move the shifter back, so I decided to shorten the shifter bracket.

The shortest you can get these guys are 4.25 with the stock setup, there is another setup that uses a different collar on the shifter, but at ~$500 that is a bit insane, instead I put that money towards a TIG welder. That was a big hit, but it is pretty cool to be able to weld aluminum among other things.

My transmission annoyingly didn’t come with the shifter, so I went off and bought one online that had decent reviews and a stock spring.

After finding out all my shift knobs I had collected were either too small or too big, I was looking online when my friend suggested I just print one. I had not messed with threads very much, but man, the shift knob was almost perfect other than a little blemish.

With that figured out it was time to make room for the transmission, that meant cutting out the trans tunnel. My design philosophy (pretentious as hell to say) was to not be project cliche if I can help it. No mismatched panels, no mismatched seats, no dragging the exhaust everywhere, etc etc. That was a bit of a problem as this tranny was so big, but with gratuitous cutting I was able to lift the whole shifter assembly into the cabin to keep the transmission from dragging let alone the exhaust.

That brought in the problem of my old brake setup getting in the way and leaving so little room that I could not even run the fuel lines up top and the stock brake line fouling the way it was routed.

So I pulled the proportioning valve inside and figured while I was here might as well fix some old issues, I replaced the questionable brass fittings, and added a proper ball valve, and decided to throw in my home made bearing loaded hand brake as well.

Looks quite handsome I think.

Fuel lines were shifted so now they run along the driver side away from the exhaust which is a win win.

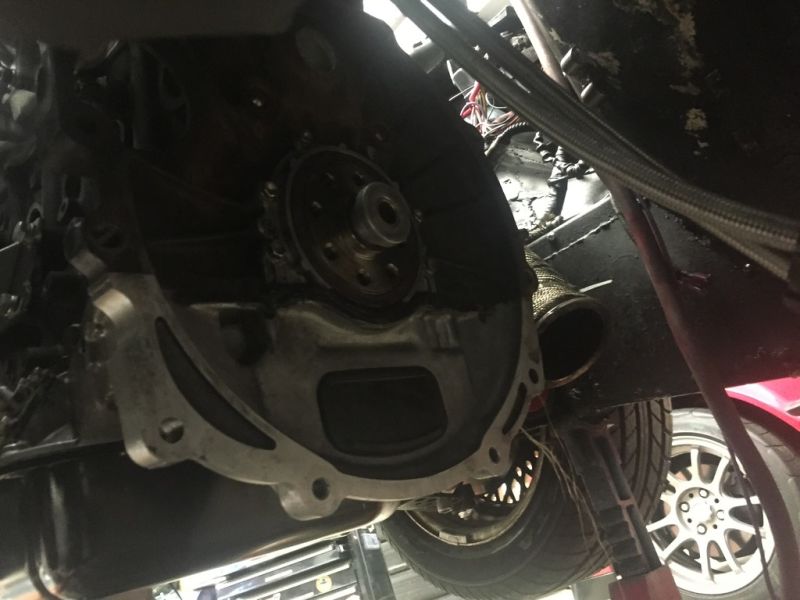

With the basics mocked up it was time for the transmission to come off.

I picked up the adapter plate from a local for a really good deal, he was really burnt out on his project that had dragged on for so long, unfortunately I didn’t put that together until now that I had one of the earlier adapter plates. I appreciate that they made them, but man there were so many faults with the earlier model. The starter was meant to be bolted in from the transmission side (if the starter goes you have to drop your transmission to change), the bottom holes are threaded to a massive size (bolt heads won’t clear the bell housing, might be able to use socket heads), no dowels for the transmission (lining up the transmission was super terrible), and the adapter for the clutch pilot needs to be installed only partially and is an interference fit with the flywheel (you can’t have both....). Instructions found online were also one sheet and annoying at best. That is something printing has taught me, you need to do a few iterations to work out the bugs, hard to do when you have to do bulk orders to save on the cost I suppose.

So I installed the bolts for the starter

Then welded them in after centering it with the starter, so that problem fixed.

The dowel pins I’ll have to live without, and the I have socket cap screws to try for the bottom and hope they will clear and I can get an allen wrench up there to tighten them.

Given this was a $1500 kit new, I hoped I would be in the clear, but nope, should have gone with my gut feeling and test fitted everything. Even now I have sneaking suspicions about the clutch throwout.

Plate went on with the bolts securing it getting red loctite, I’ve had bolts strip because of how strong this stuff is. People say to use this on everything which seems insane to me. Also pictured is the illusive 243. That one is listed also as a sealer on top of a thread locker apparently, it should be used for things like the flywheel bolts which are through holes to the crank and not sealed will leak oil.

The clutch pilot adapter needs to go on next as you need to measure the depth and leave a cap so that the input shaft has good engagement, which the flywheel covers up. A better design would be to measure it so you can just bottom it out in the crank and not worry about it.

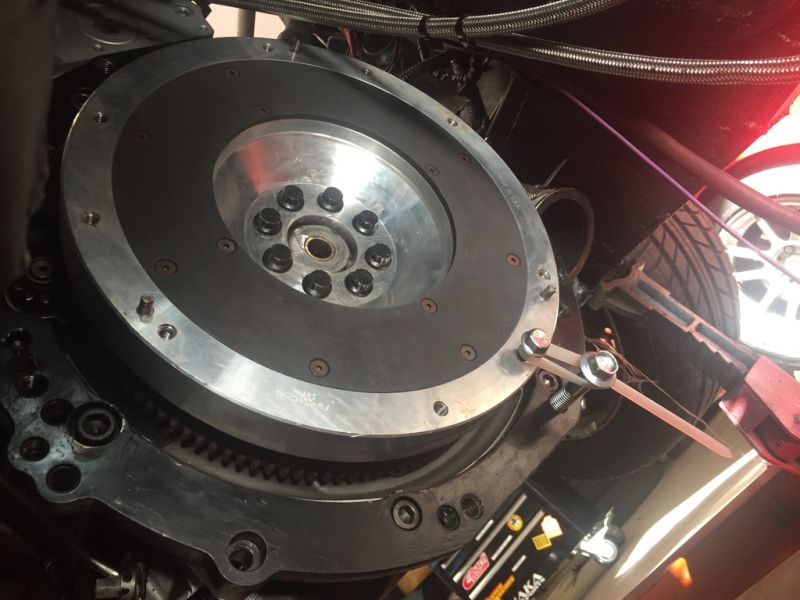

Then the massive flywheel secured with bolts. Nice little trick for holding the flywheel to torque the bolts, I had 80lb zip ties available if not a strong piece of rope or chain will do nicely.

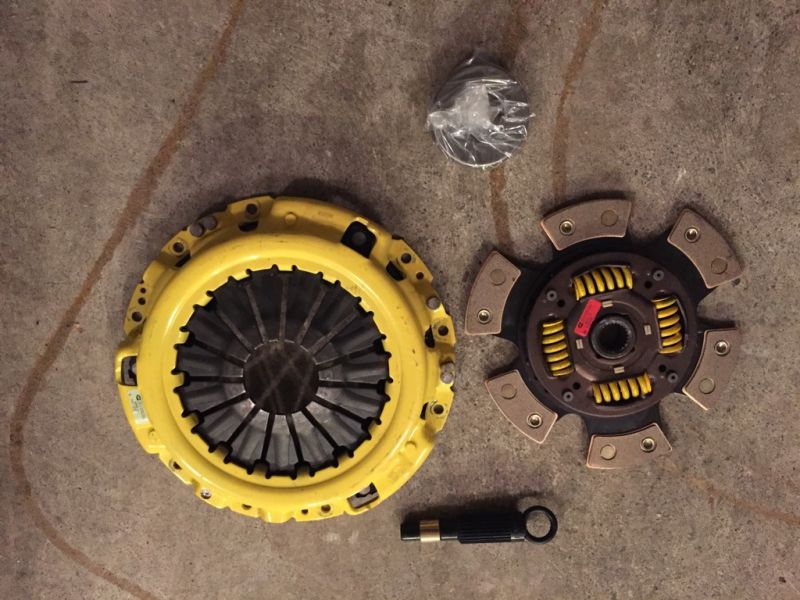

Then the clutch kit. I was able to find second hand, given the last kit I ran I put on 400 miles or so I figured I could get away with one to roll around with and decide if I want to go more serious later on. This is a south bend super street kit with quiet disc good for 530ft/lbs or something of that nature and supposedly very quiet as well.

If I decide to max out the turbo or go insane I also have an ACT xtreme kit good for 670ft/lbs of torque apparently. This one is listed though as I’m not a big fan of puck clutches.

The transmission was a pain, trying to balance it on a few jacks was nigh impossible, in the past I just muscled them in, but this things was for too heavy, I have a few smashed fingers to show for it. I ended up getting a transmission jack and leveling the car since there weren’t any dowel pins to help guide it in. I can’t quite get the top two bolts, but I’m ok with that. Given the massive casting I don’t think this trans is going to pry away from the face without the top two bolts.

I still had a plate on the driver side so I just drilled through that to hold the transmission. On the passenger side the plate was too far up to reach, the only flat part was a bit further back so not quite even, but it supports the transmission, the hump is just in case I have enough room to try an run the exhaust tucked again.

It really is some of the little things that do get you though. Several bolt runs, tools, other small bits, they all really add up.

If anyone needs a 350z clutch or a full JZ setup R154 let me know :)

P.S. for those of you who may keep track part 52 is written up but not ready yet.

Reverse light pigtail - 14

Shift knob - free :D

Bolts - 70

Shifter - 70

Shifter spring - 15

Metal - 60

Transmission - 700

Adapter plate - 900

TIG welder and accessories - 1500

Subtotal: 3224

Total spent - 32,982