It wasnt catastrophic failure more of a fizzle, First let’s run through the photos.

The Turbo oil Return fitting location wasnt decided until the exhaust was finished and the engine was in the car. It occurred to me the only return location was the sump just under the crank pulley, so I drilled and tapped the the fittings in car. This left shards of aluminum floating around in the oilpan and laying in the crankcase, draining the oil afterwards evidently didnt remove many of the bits of aluminum.

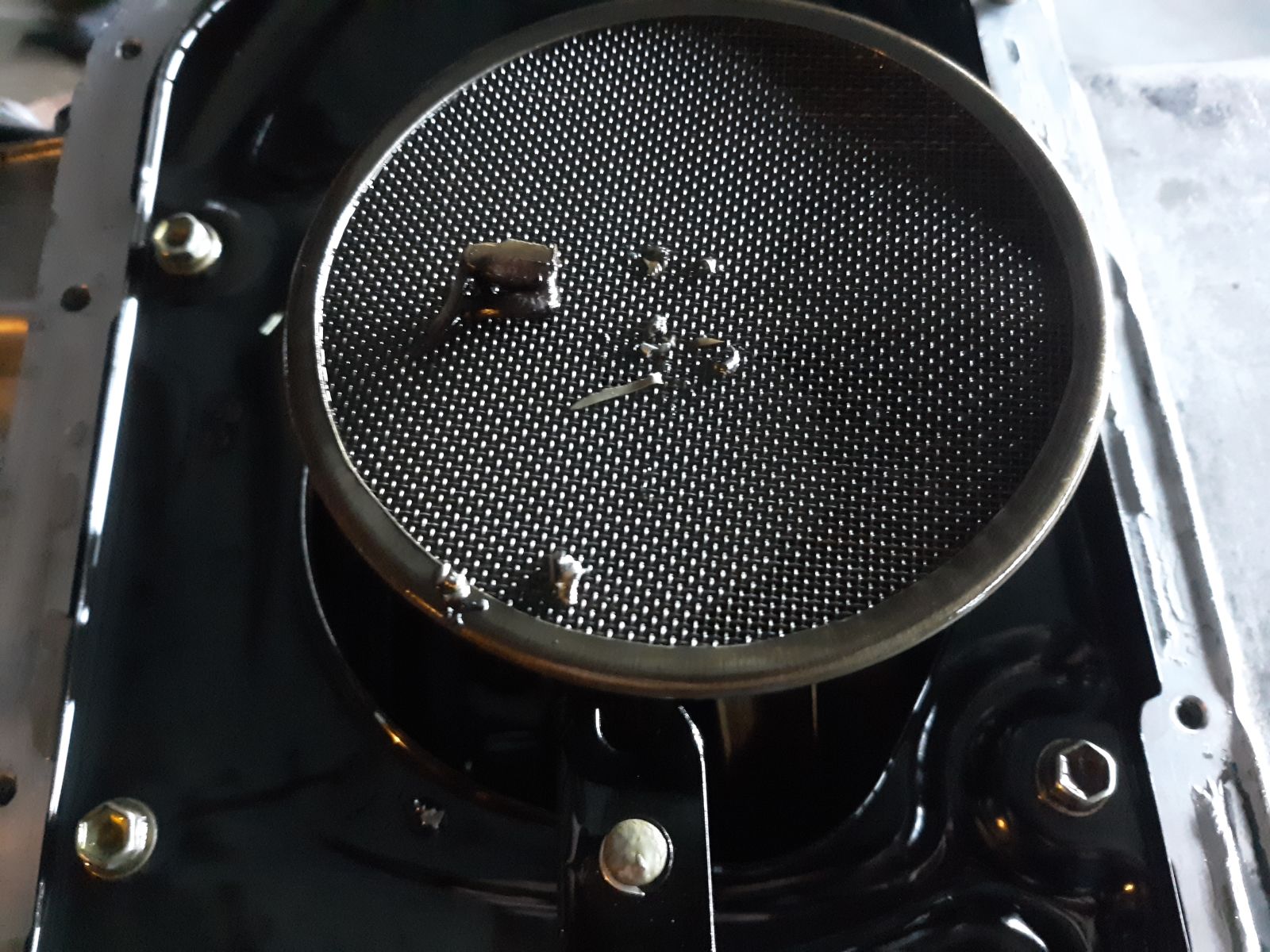

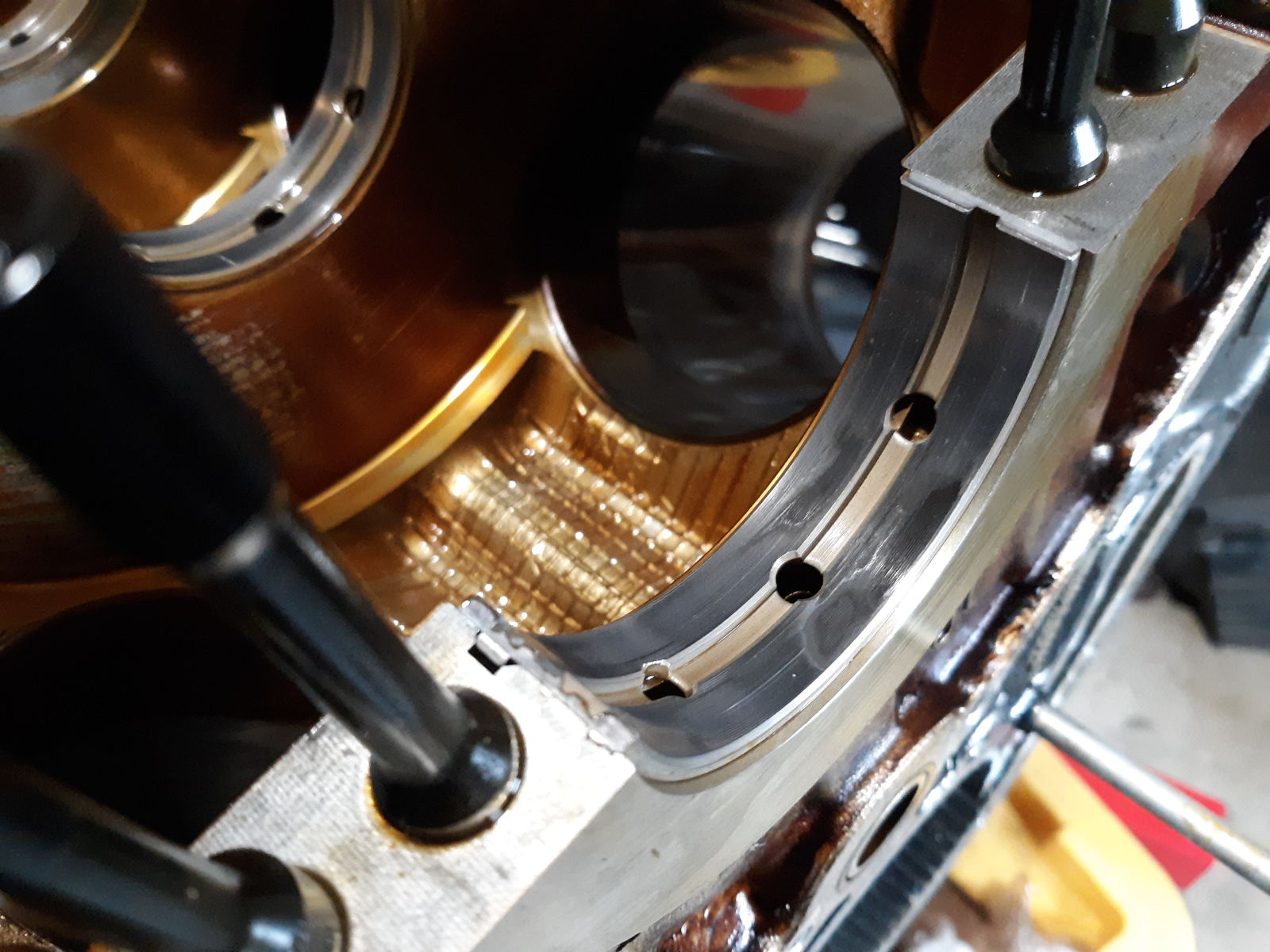

The shards got sucked into the oil pump getting flung under the pistons to get caught in between the cylinder wall and piston marring the surfaces.(which caused the blowby that was leading to turbo drain issues). It also got caught in the main bearing surfaces leading to the wear shown above.

Next step will be a rebuild using stock components save for Cosmetic head gaskets(potentially a lower compression ratio closer to 9:1 instead of 10:1) also plan to balance the pistons/ rods since I’m in there.