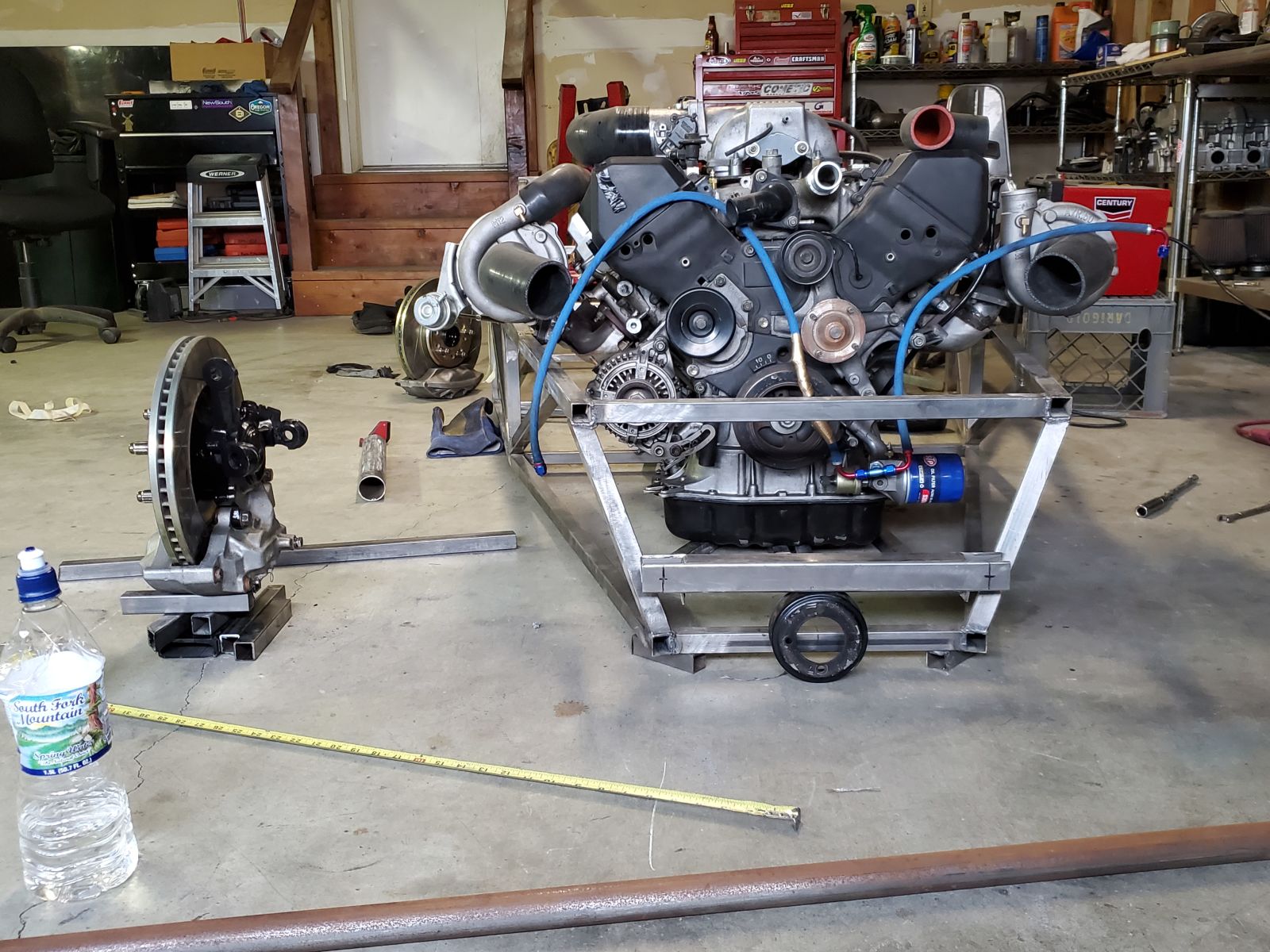

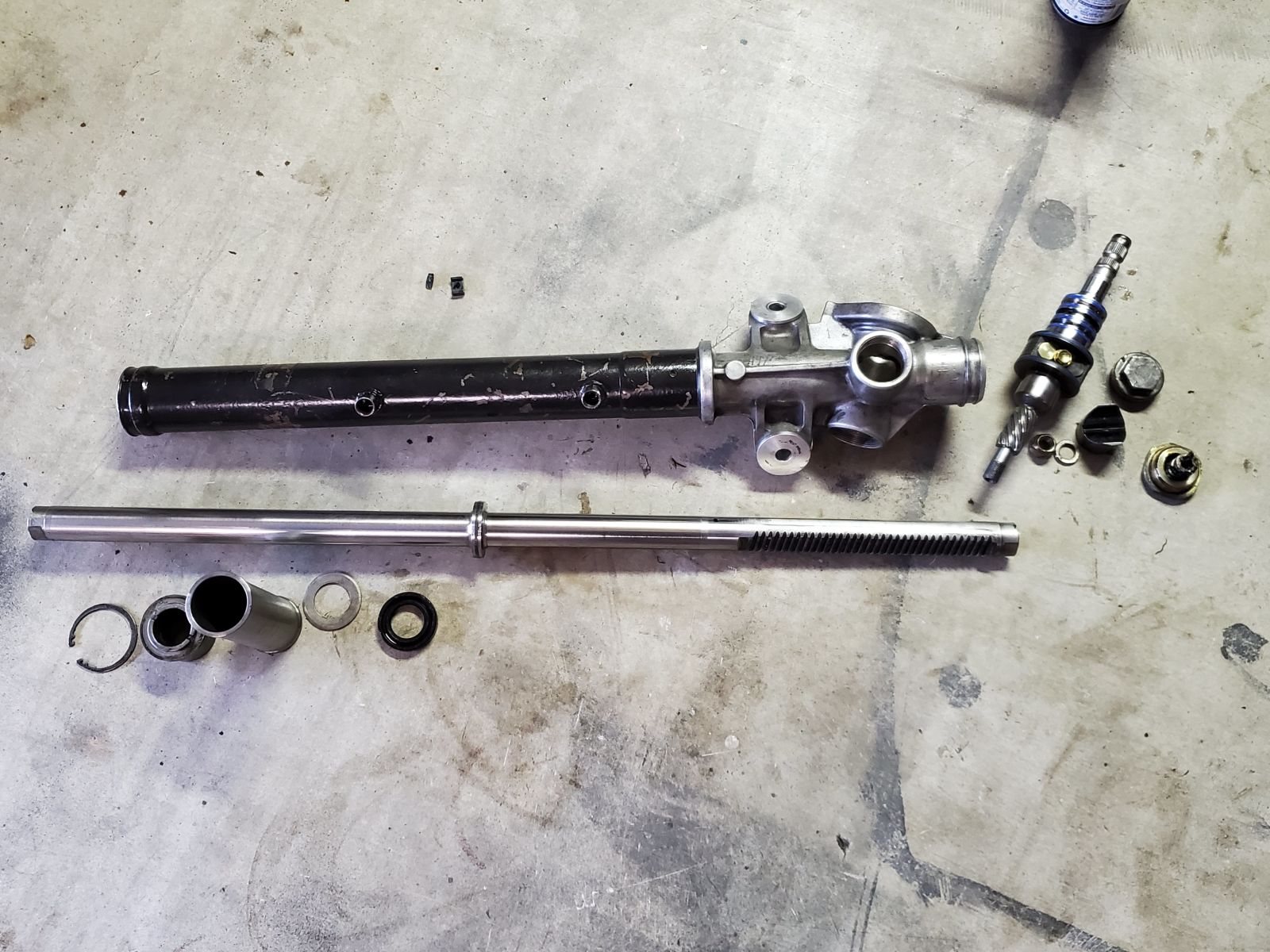

Shortened and de-powered the old sc400 Steering rack.

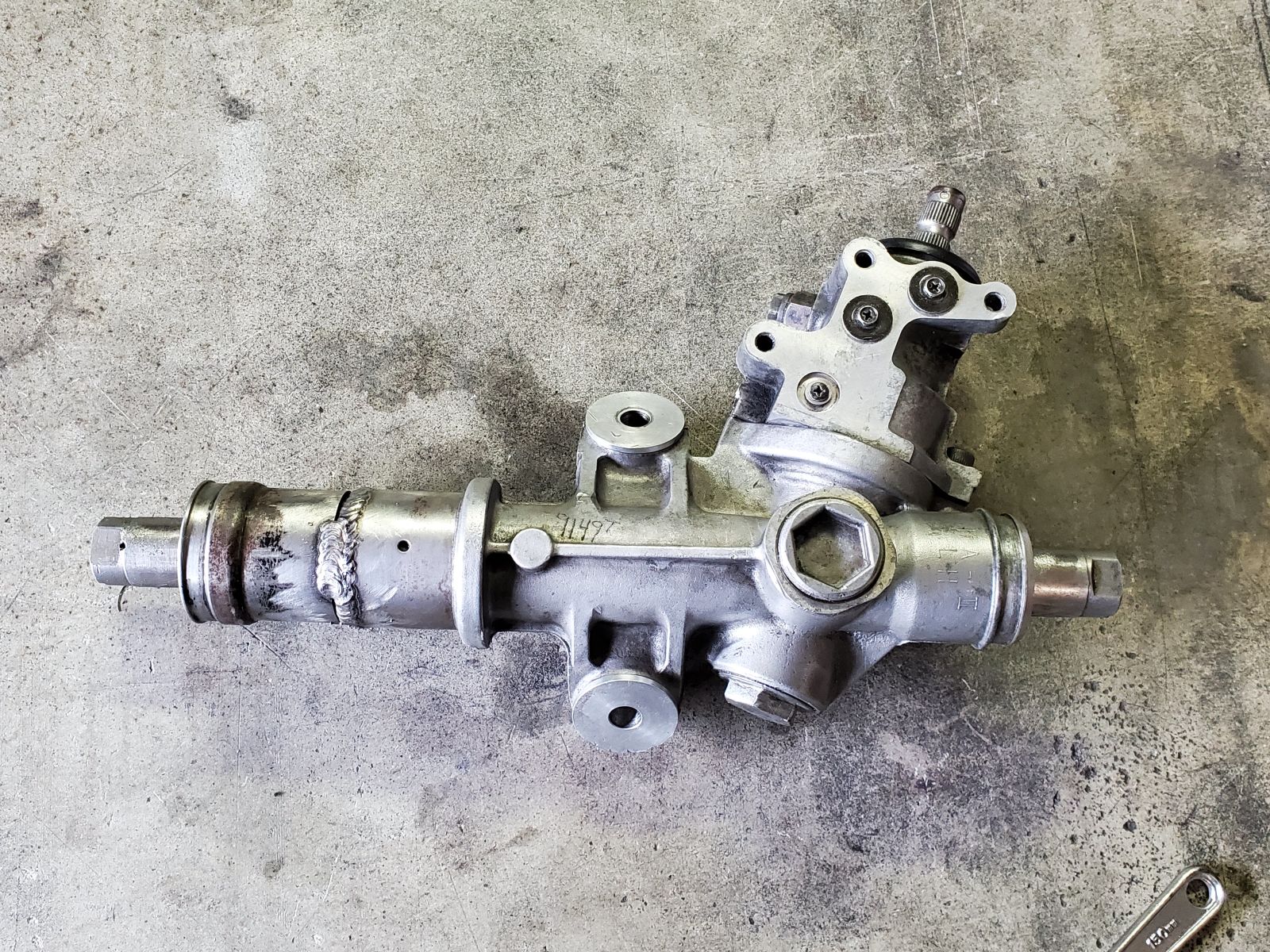

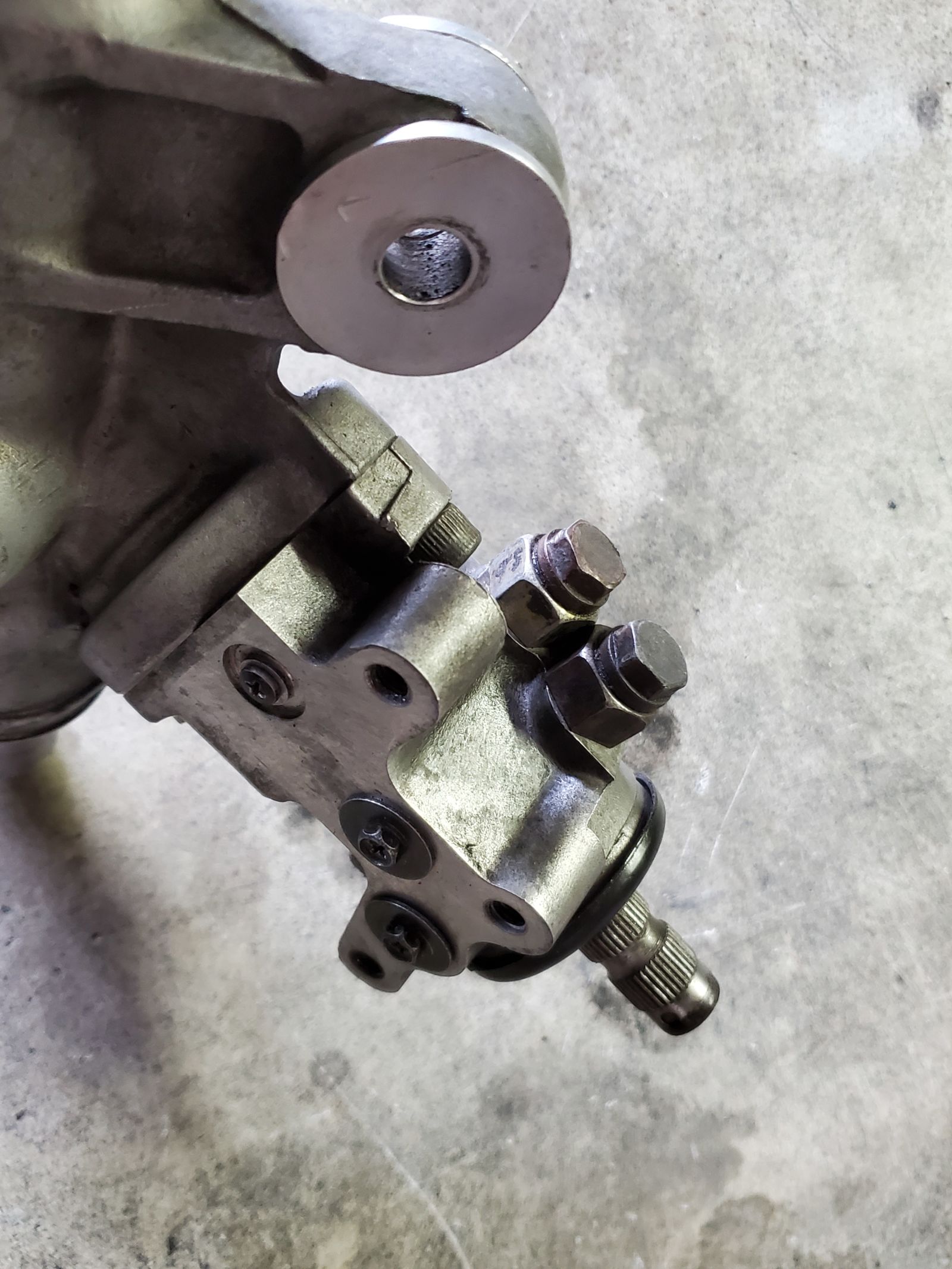

Its gone from roughly 29" to 15.25", the process was; tear it apart, cut out the middle section (orange circle), weld the end back on at the desired length, screw around with welding its centering bushing to the body (red circle), fill it with grease, leave off the variable pressure system, and plug its holes with interior screws.

Advertisement

Advertisement

Advertisement

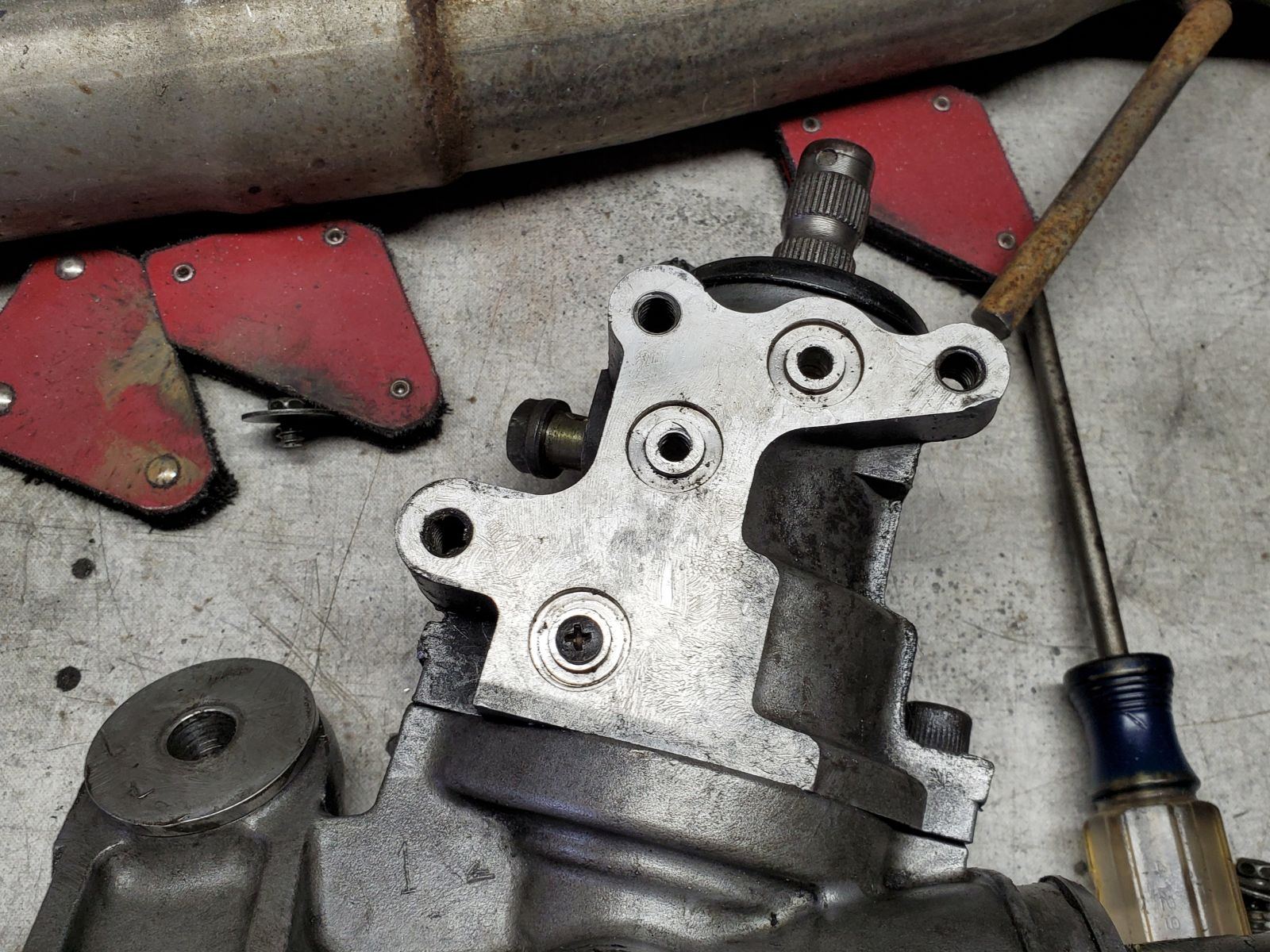

With nothing under pressure all that needs to be done is plug these holes to keep dust out, nothing some parts bin screws can’t fix

Advertisement

All that’s left to do is paint the steel section of body and its ready to mount up.