Some people spend time meticulously designing and building everything in CAD, Perhaps even engaging in math. Then measuring twice, scribing meticulously, and cutting once to great effect.

This is not that, though we will use CAD (Cardboard Aided Design)

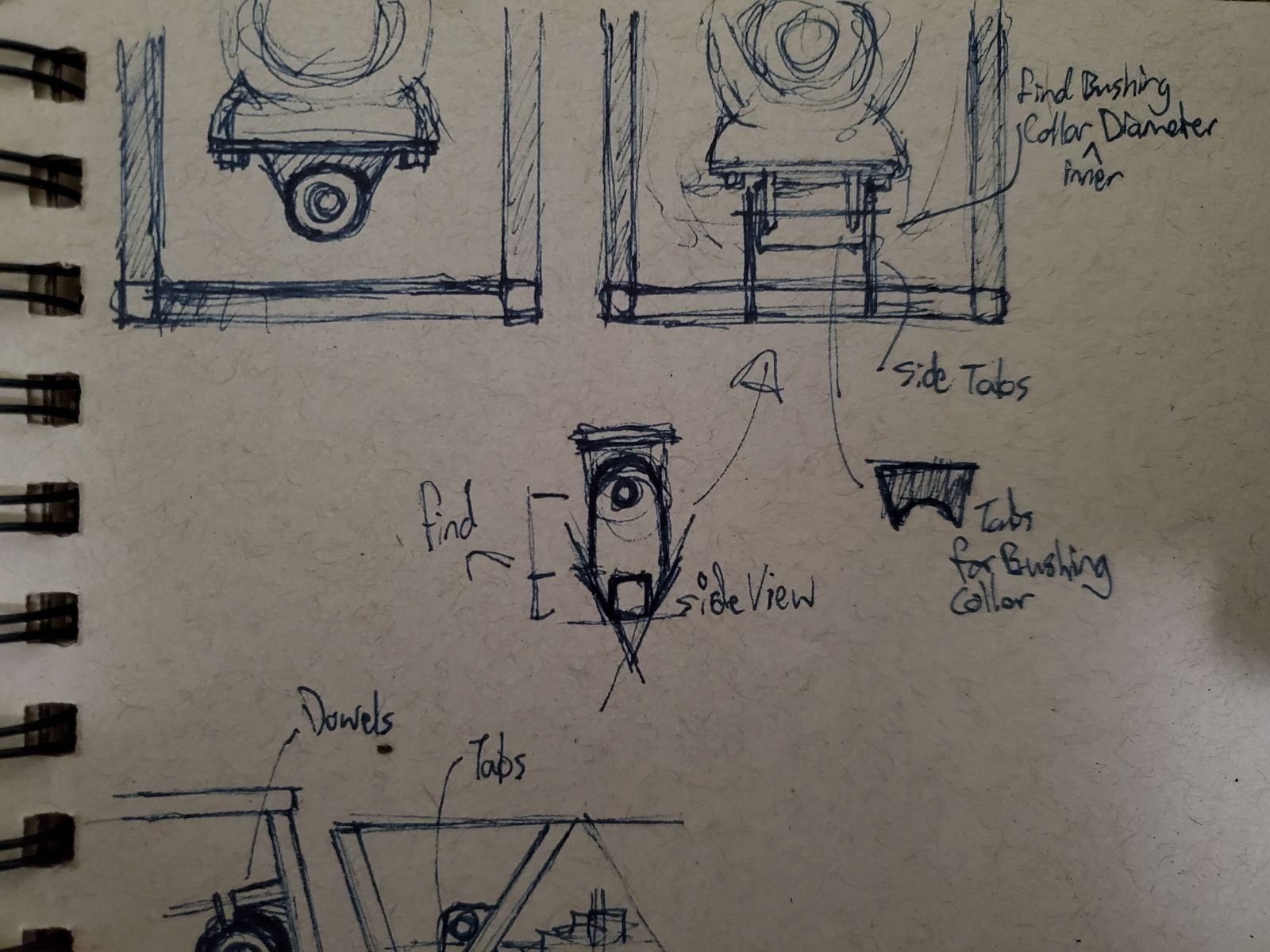

First step is to draw out what you want to make, go out and measure things, then come back and redraw it with the sizes In mind after realizing you’ve got less space then originally thought. The idea is to work out what parts you’ll need to cut out, which materials you’ll want, and what order to create the parts. You might find that you’ll need to create half of a part before having a concrete idea of how much space there is to mount it, or getting a compete weld is only possible is a certain order.

If your working with small diameter square tube, tape is a good way to get a quick idea of what it will look like in place. If its sheet metal, a full cardboard mockup is always helpful.

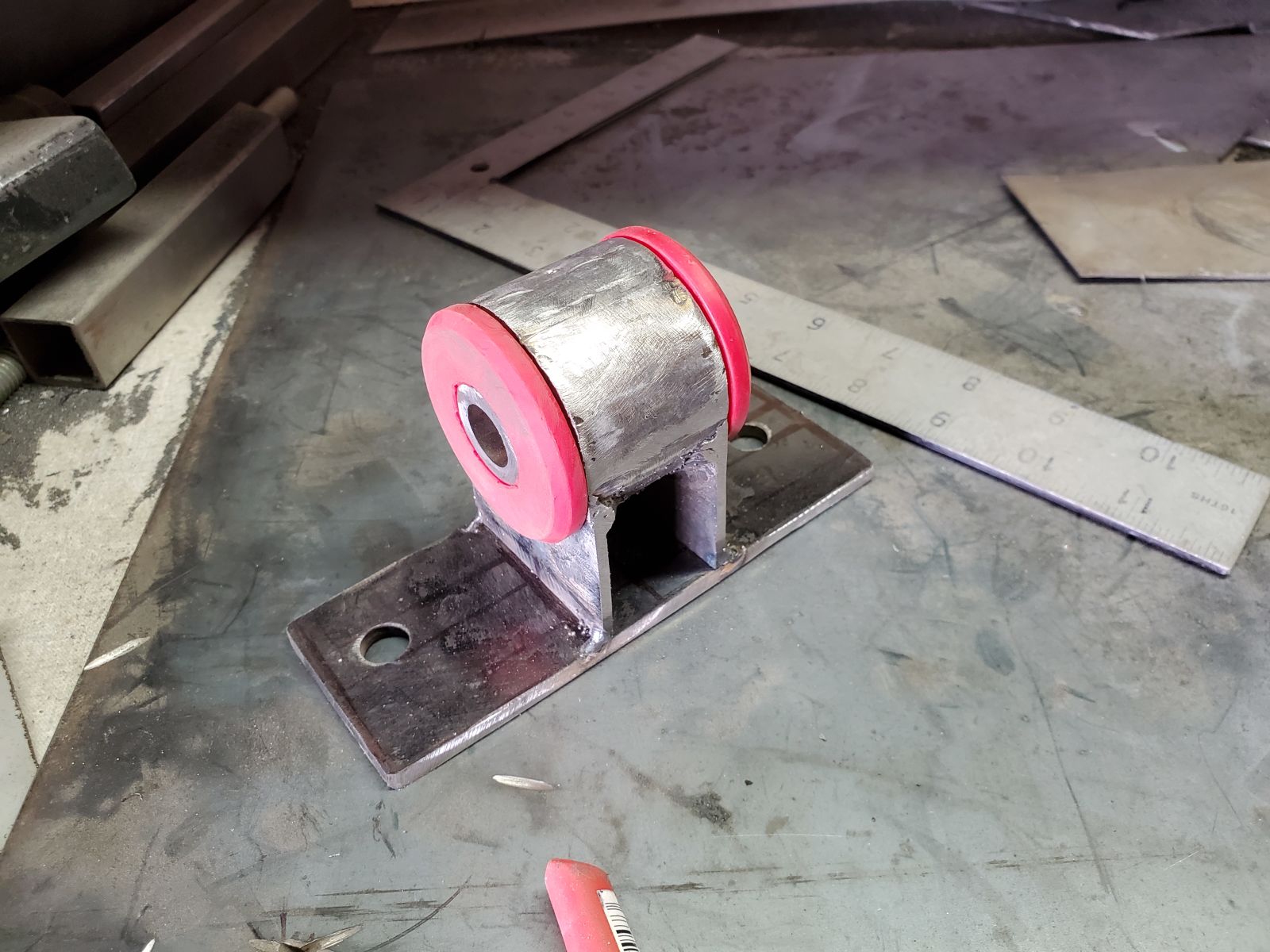

Cut an initial piece to work with, in this case it was 2" tube for the bushing. Then its to the cardboard to make a template, draw it in marker, cut it out, and keep whittling at it until it fits how you want.

Trace onto your workpiece then bust out the angle grinder, if its 2 identical parts cut both then clamp them together with vicegrips. Once clamped you can grind down both surfaces to be even, given you hold the angle grinder level.(parts rarely turn out identical without some massaging)

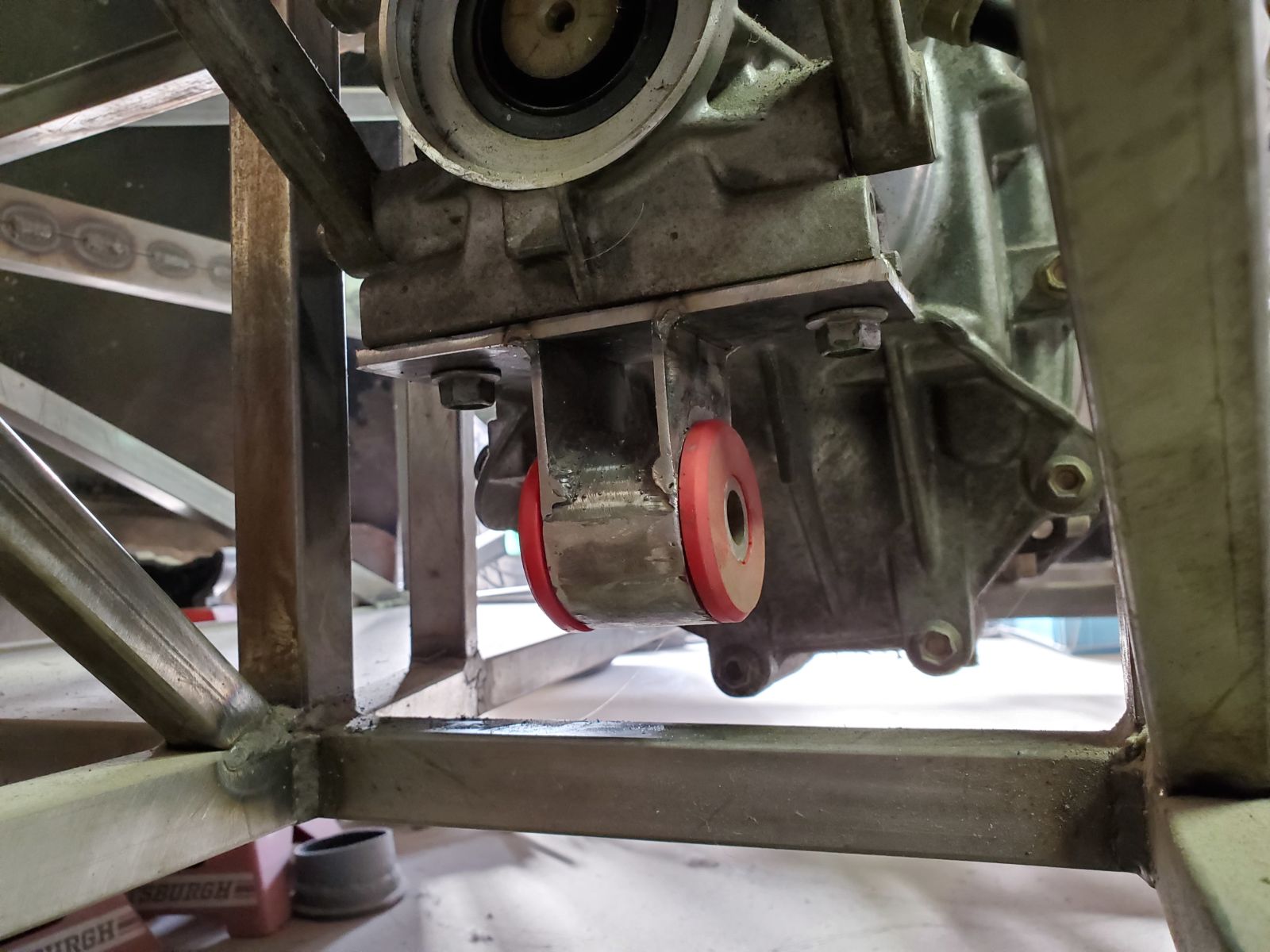

Grind until they fit as desired, tack weld until your sure its done, finish welding, Presto.