Now that all the external bits have come off, its time to get into the guts.

First, we chisel the old distributor out. Thankfully 30 year old aluminum is no match for a chisel and a sledge hammer.

Before going any further and making a mess by cracking anything else open, I decided to drain (finally) the oil and whatever coolant was left.

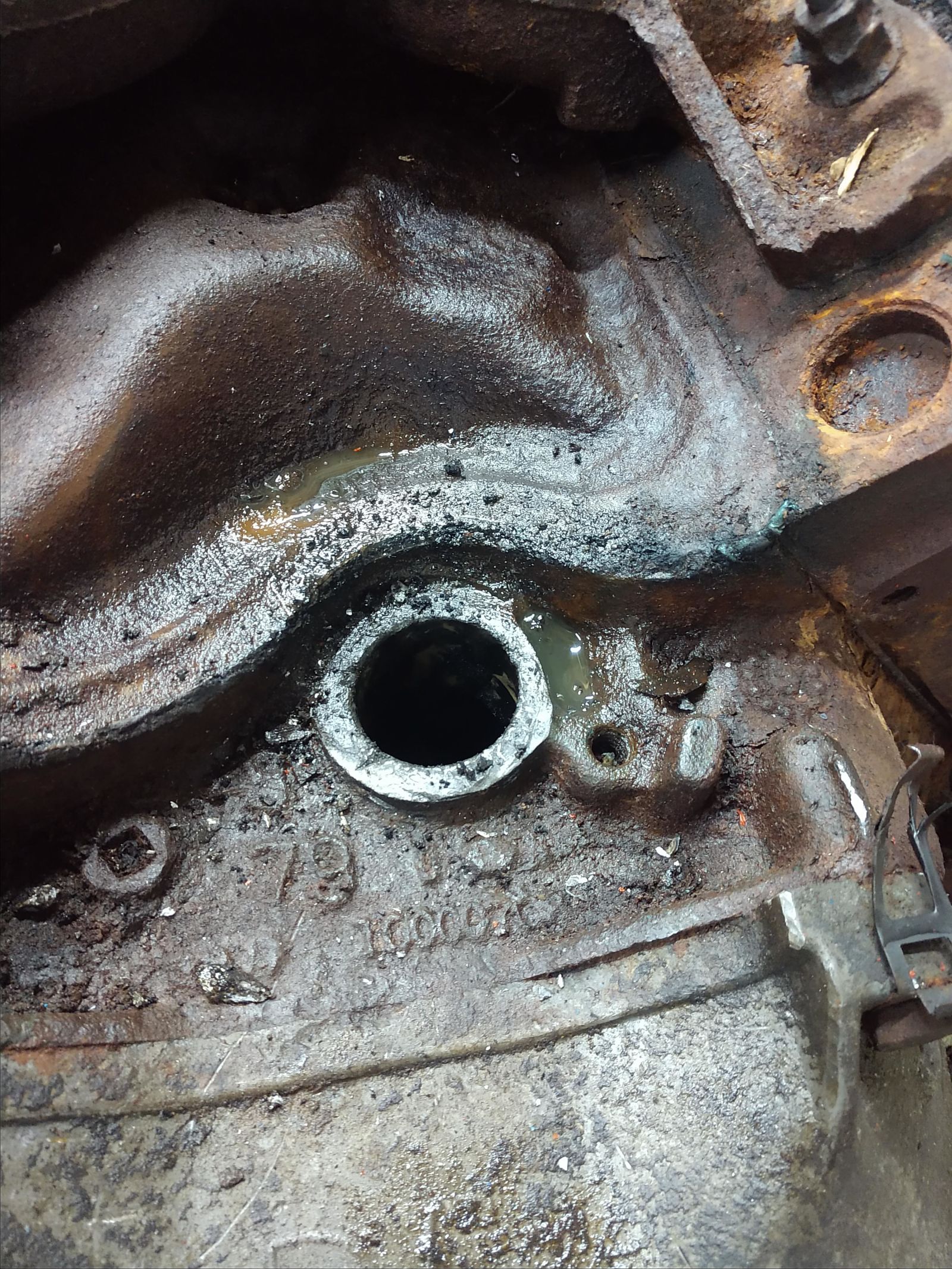

So I grabbed my 5/8' wrench (my old quick lube-tech memory served me well) and put it on the drain plug. I heard rust breaking loose, so I twisted it some more and...

I have never laughed so hard. Thankfully I was already lying on the floor on a creeper so I didn’t ROFL too much but HOLY SHIT. In 20+ years of wrenching I’ve never ripped an oil pan open like that. I guess it was rustier than I thought.

Speaking of rusty things and wrenches, attempting to remove the left valve cover punched a hole in ITS thin rusty metal with the wrench. Which was a good thing, because the bolt was so rusted and stripped there was no way it was coming out anyways. I just ripped and twisted until the cover was off.

The rest of the disassembly went MUCH smoother, thankfully. Valve covers off...

Water pump and intake manifold off next

Lots of shit under the intake. I’ve now shop-vac’d garbage off the motor FIVE times now....

Valley pan off

And before I pull the crank pulley and timing cover, I rotated the motor over to get to the flexplate to torque converter bolts. Which, after removing the brand new starter I had put on it last year to see if it’d run, was by far the EASIEST thing I’ve done to this whole motor, if not the whole car. They came out like butter. I also cracked loose the bellhousing to block bolts in preparation for removing the trans... those ALSO came loose without drama.

Also of note: More Pontiac Blue paint!

I stuck a punch in the flywheel to keep the crank from rotating, and removed the crank bolt. Then after fiddling around with my pulley puller and realizing the pulley was just Too Damn Big for it to work, I thought to myself “Self, the last few things were pretty loose, lets see if we can just pry off the pulley with a pry bar”.

Y’all, I barely breathed on it and it slid off. So much for needing a puller. I also yanked the rockers and pushrods after watching them do their thing. A few weren’t turning so I’m sure some of the lifters were stuck. I’ll get those out eventually and asses the damage.

Even more Pontiac Blue! Crank pulley off, drain pan in place, the front timing cover was next. I didn’t realize it was aluminum. It should clean up nicely and make a fancy wall hanger or something.

I then found another reason why this car may have been parked all those years ago to rot, when it seemed to me like it was still in nice shape, and running.

Lots of chain stretch, and a very worn and noisy fuel pump eccentric. I remember hearing some squealing when it WAS running, now I think I found why. Might have been the reason why the guy gave up on it.

Oh well, I’ll add it to my every growing pile of junk parts.

Part 3 we’ll see if I can remove some exhaust manifolds (already broke one bolt, yee) or at least the Y-pipe so I can pull the heads. Then the trans can come off, and maybe I’ll get to the bottom end and pull the oil pan, crank, cam, and pistons. Or I’ll just leave it until I get the bodywork done on the Trans Am, so I have an engine stand to use to make all that a lot easier...