“I found a stick! Wanna play?”

Not now, Rocky. It’s time to account for the weekend projects. I started with a trip to the big box store for some lumber. I had them rough cut the 4x8 sheets I needed down to the size I needed for my big project and to make them easier to transport. Everything fit neatly into the Outback. The lawn trailer is an excellent tool for moving large lumber without breaking my back.

The first project was to get started on the hole repair. This is one of the two upper cabinets that will go back into my office.

I used a hole saw to round out the hole in the cabinet and the next size up to create a plug. I used a combination of a drill and a sanding block to get the plug down to size.

The plug has been glued into the hole and awaits further processing. The other hole that’s on hold is the one in the office wall. It needs sanding and texture.

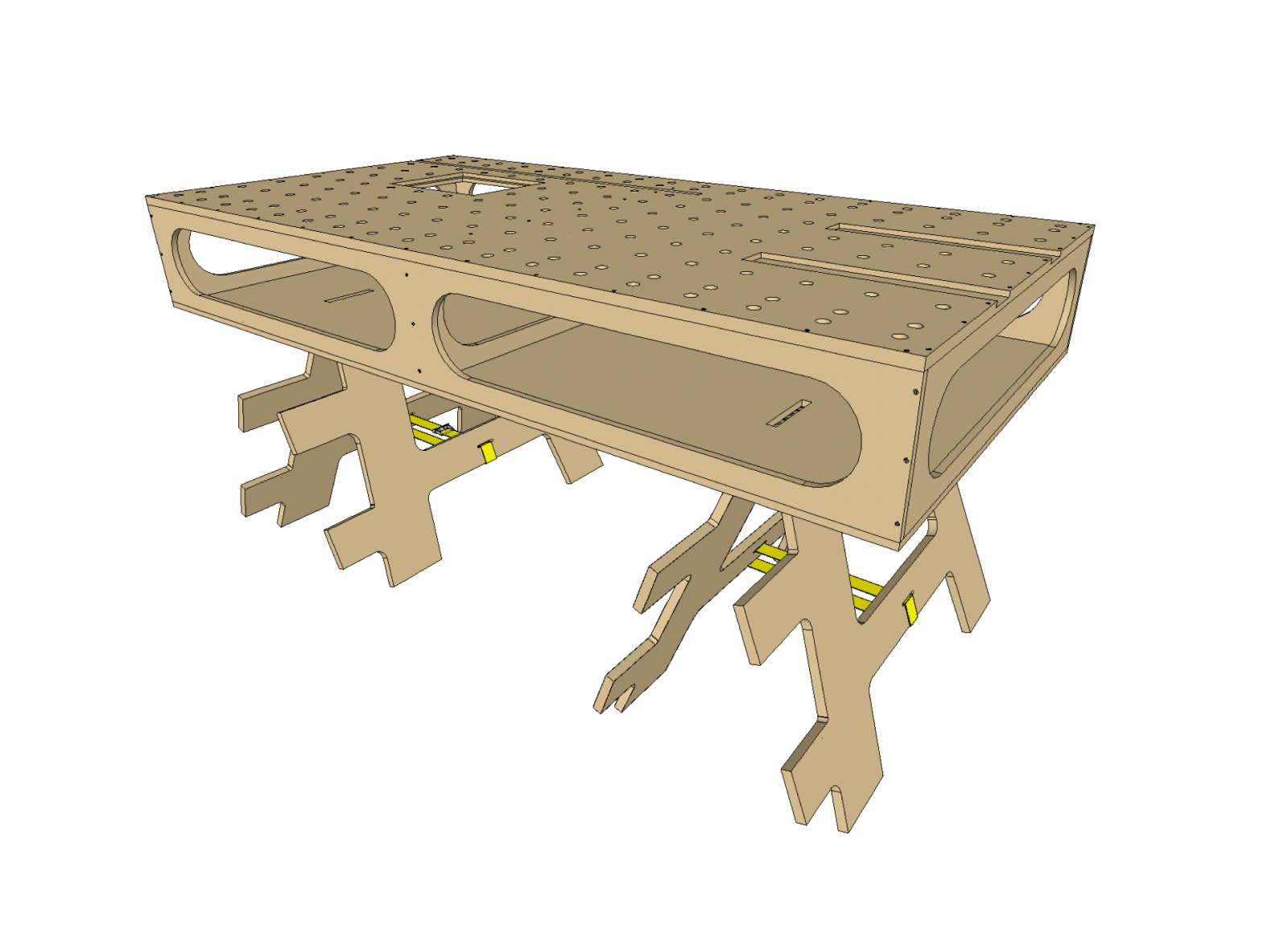

The most fun was had back outside. The little workshop is in desperate need of some organization. I keep misplacing tools, so I decided it was time to get started on a proper workbench. I picked up the plans for Paulk’s compact workbench. It’s still a 3x6 work bench, so it’s not tiny, but it’s about the right size for my needs.

One of the big advantages is the open framework. I’ll have a place to set tools down without them interfering with the worktop. I wish I had taken more pictures of the build process, but the most challenging thing so far has been getting the openings right without using a track saw. I got them rough-cut, then used a plane and sander to get them closer to right. Yeah, I know I need a lot more practice.

The big trick is getting the curves to match up with the straight edges. The only tool I have for cutting the curves is a Rotozip with a radius cutter. It’s not the best tool for cutting plywood, but the end results are acceptable.

I still need to build the legs for it. I’m not going with the saw horses in the original design. I want fold-out legs with wheels so I can move it around more easily. I’ll have to match the height with my table saw so it works as an outfeed table. I also need to make the jig for putting the holes in the top for the router plate and the bench dogs. Those can wait for now. I’ll get it on legs and then use it to work on my other projects. My wife’s birthday is coming up and she had a special request this year....