One of the problems we’ve found with the performance aftermarket for the Hyundai Genesis Coupe is that many critical parts are only available at the extreme ends of the cost spectrum: either super-cheap chintzy bullshit or painfully expensive race-grade excellence. While we generally come from a buy-once-cry-once school of thought on our automotive modifications, we aren’t exactly value-averse either. Sadly, despite our best efforts, our rear end rebuild ended up similarly expensive to our previous builds. And here we thought a Korean sportscar would be cheap to modify...

We really tried not to buy an expensive driveshaft. Honestly, we did. We spoke to a few different driveshaft makers, with the excellently-named Shaftmasters showing the most promise. However, in the end, we were flummoxed by the Genesis Coupe’s particular OEM driveshaft design.

Rather than employing a traditional spline-drive design, our driveshaft has an odd bolt-in design. This is not something that any old driveshaft maker is willing to reproduce, narrowing our selection to the two biggest names in the business: Driveshaft Shop and QA1.

Driveshaft Shop already had off-the-shelf options available for us, but they were total overkill for our application. Their 4 inch diameter aluminum and 3.25 inch diameter carbon fiber driveshafts are both rated for one thousand horsepower. Project Hoondy will never, ever, make anything like that much power. We really would have preferred a narrower, more modest driveshaft.

QA1 could have made us such a driveshaft. We where very interested in their 2.5 inch diameter carbon fiber option which is rated for five hundred horsepower. This would have been absolutely perfect for us, leaving us a healthy overhead for future power mods, but not veering totally off the deep end.

Unfortunately, it just wasn’t to be. Getting accurate enough measurements for QA1 to make a driveshaft for us would have involved removing our OEM driveshaft. Given that Project Hoondy was still a daily driver we just couldn’t afford the downtime.

So fine! Fine. We bit the bullet and went with Driveshaft Shop. We had concerns about clearance issues with our custom exhaust, which compelled us to go with the more expensive, but narrower, carbon fiber option. Lower weight and better shock absorbing qualities were enough of a bonus to make us willing to swallow the added cost. Our friends at GCtuner also secured us a 15% discount which took the sting out a little.

Next on the list of things we probably spent too much money on are these babies:

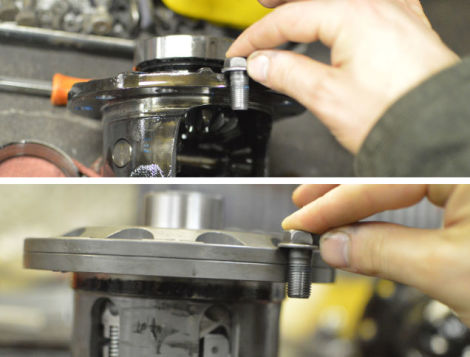

Way back when we installed our Cusco RS limited slip differential, we ran into a problem with the length of our OEM ring gear bolts. They were too short for the wider case featured on the Cusco RS. Short on time, we settled on a set of regular-ass grade 10 bolts. We were fairly boxed into that option at the time due to the odd combination of super-fine 1.25 thread pitch on a large, short M12 fastener that our ring gear required.

Years later, after a deep dive into the ARP parts catalog, we discovered that flywheel bolts for Nissan RB25 and RB26 engines featured the exact dimensions we needed for our ring gear bolts. They come in a set of six, so two packages of them would cover our need for eleven bolts. Not only were they much stronger than our old bolts, but they were proper shouldered bolts rather than fully threaded. While, in all likelihood, our old bolts would have stood the test of time they made our damn teeth itch. For $80 we were happy to replace them with proper ARP hardware while we had the diff torn apart anyway

Our final all-out splurge on this build was on axle shafts. While the Genesis Coupe axle shafts have pretty bullet-proof CV joints, the shafts themselves are brittle and known to break. Driveshaft Shop does a set of 300M axle bars, but they require you to disassemble your old axle shafts so as to re-use the CV joints. This is work best left to a professional mechanic. Such a process adds even more cost onto the $520 price tag for the Driveshaft Shop axle bars.

We’re willing to tolerate high cost to some degree, but the combination of expense and inconvenience made us shy away from this option.

Happily, we found an alternative.

A little company based out of California called Insane Shafts has been making a name for itself with super-strong axle shafts. Their products come fully assembled and ready to go. They make two options for the Genesis Coupe, shafts rated for 500 and 1000 horsepower. We went for a set of their 500hp axle shafts. At $800, they cost well more than the option from Driveshaft Shop, but considering the reduced labor and increased convenience we were willing to take the hit.

Also, full disclosure, we contacted Insane Shafts in search of a discount and they offered us a partial sponsorship deal which netted us $100 off and free shipping.

We still had to address our dying rear suspension arms. While chances were that not all of our OEM rear arms were bad, it made sense to replace them all while we were going to the trouble of tearing the entire rear end apart. There are a variety of aftermarket options available, but nearly all of them are pure race-grade parts with completely unshielded joints. These parts would not hold up to the rigors of year-round street driving, especially in the winter.

That really left us with only one choice. ISR performance has been making suspension arms for the Genesis Coupe since right after the platform was introduced. They had always been a middle-of-the-pack option, playing second fiddle to the likes of Cusco and Megan Racing. However, they recently introduced their beefier Pro series control arms that feature fully sealed rod ends and bushings. These parts should withstand long-term exposure to the elements much better than the other options available to us.

And thus the parts selection for our rear end rebuild was finally rounded out. Now, at long last, it was time to assemble this expensive pile of steel and carbon fiber into a bomb-proof rear end. Tune in next week to see how it all came together!