While all of Project Hoondy’s modifications have involved a long planning phase, the rear end rebuild really tried our patience. The sheer number of parts involved as well as complications in getting a swaybar to fit on our new rear subframe delayed the build to previously unseen levels. What we hoped would take a couple of months ended up dragging on for more than a year.

Part of the reason is that we actually had to abort the mission when the build was at a less ambitious phase. We’d originally planned to slap the 4.18 gear set and carbon fiber driveshaft into the car by themselves with our buddy Andy’s help. This was before the rear end developed its wandering issue. We were defeated by the bolts that held the lower control arms onto the subframe, we just couldn’t get them loose for the life of us. Since we had planned (rather foolishly) to re-use all the control arms and hardware we were unwilling to remove anything destructively.

We also discovered that our driveshaft didn’t fit. Driveshaft shop had sent us the wrong unit, possibly the one they make for the 2.0 liter turbo version of the Genesis coupe. Either way, we weren’t able to install any of our new parts on that occasion. We arranged to have the driveshaft replaced and made a plan to return to the build.

Shortly thereafter, we attended a drift event which is probably what provoked the rear end problems that developed almost immediately afterwards. That’s when we decided to get more ambitious with the build by adding the subframe swap and full control arm replacement. This added considerable expense to the build, which delayed us further as we acquired all the parts.

But finally, at long last, it was time.

To say that the scope of this build had outgrown our ability to complete it on our own would be a massive understatement. After the fiasco that was our first attempt, Andy was unwilling to help us make another go of it and we certainly couldn’t blame him.

Happily, at this point the car was living in the Denver area and there are many excellent mechanics local to it. The grassroots drifting scene there is strong and there are several shops that feed it. While many of them are good, one in particular stood out to us early on.

After Hours Autosports is a small shop located in Golden Colorado. Started as a one-man, two-lift operation, it is headed up by the talented Mr. Justin Chestnut, often supported by his cool-ass father Bob. Though small in size, After Hours has turned out some killer builds. They run the full gamut from regular maintenance to full-on drift machines. European, Japanese, and Domestic, they do it all; though over the years they have come to specialize in BMWs due to Justin’s own E46 drift car.

Suffice to say, they were more than well-equipped to take on our project. Though, despite their high level of expertise, they offer very good value for money as well. By keeping their operation lean, they offer one of the lowest shop rates in the area while still turning out top-quality work. They even proved this out to us when we had an unexpected fuel pump failure on Project Hoondy. Justin had us sorted out and back on the road in just a couple of days for much less money than we’d been quoted by a local “import specialist” shop. After hours earned our repeat business and then some, making us excited to bring the car back for our massive rear-end build.

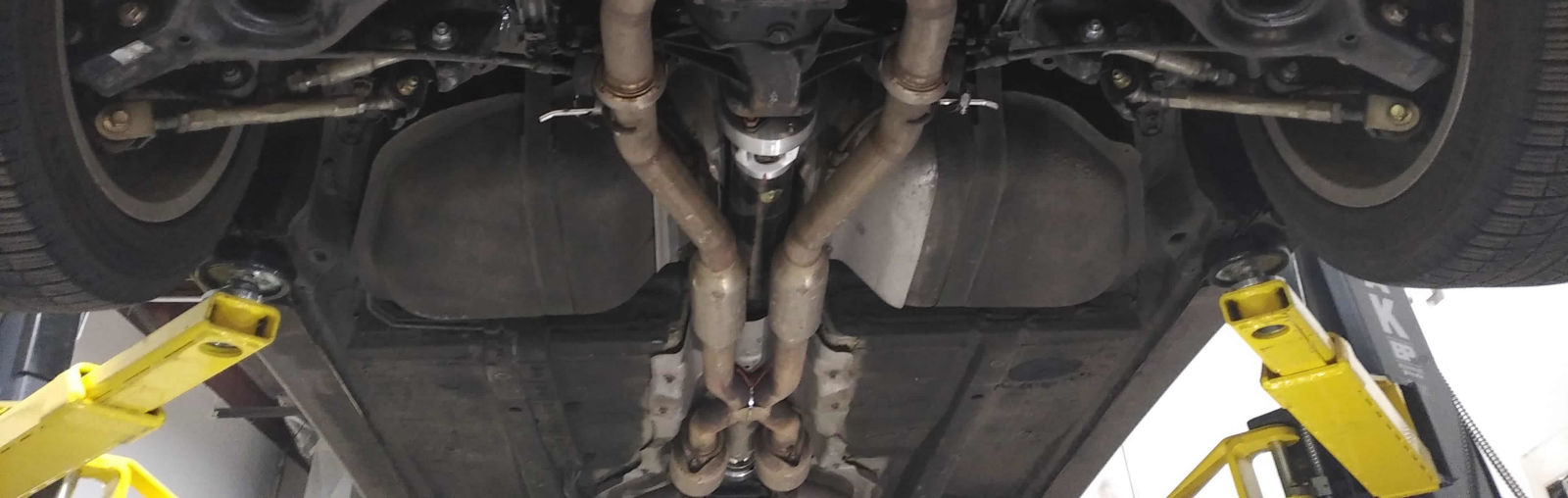

While we were daunted by the scope that the build had grown to, this sort of thing is absolutely routine for Justin and his crew. Rear end swaps, upgrades, and rebuilds are some of the most common procedures in the drift world; such as this tasty rear end refresh done for an S13 earlier in the year:

Once they had their hands on Project Hoondy, the build went by in a blizzard of mechanical action. Out with the old:

...and in with the new:

The sedan subframe truly is drastically beefier than the Coupe unit, which itself is already quite heavy-duty in nature. Compared to the delicate little S13 subframe above, the Genesis Sedan assembly is humongous. Massive hydroformed legs, chunky reinforcing straps, coffee-can sized body bushings, it looks more like it belongs on an SUV than a sleek sports car. While the weight penalty isn’t the most performance-oriented feature imaginable, the sheer strength of this assembly lends itself well to the rough-and-tumble world of drifting and hard driving.

After Hours made the install look easy, even when we were thrown another curve-ball from Driveshaft Shop. It turned out the replacement driveshaft they sent us was also too short. We were furious, it was a big enough cock-up the first time, but making the same error twice in a row just speaks to a level of carelessness that says nothing good about their attitude towards customer service.

Luckily, After Hours had both enough experience with Driveshaft Shop and driveshaft modification know-how to take the problem in stride. After a stern talking to over the phone, Driveshaft Shop rush-shipped a custom adapter plate that arrived the next day.

At roughly half an inch thicker than the standard plate, this new adapter took up the extra length that the driveshaft was short by without us having to go through the three-week agony that was the return process we experienced the first time.

While Driveshaft Shop deserves at least some credit for finally getting their shit together on this project, we mostly give props to After Hours for identifying the problem early on and organizing such a quick solution. Most shops would have thrown their hands in the air and left it up to us to deal with Driveshaft Shop and their protracted RMA process.

Bob also found that our fancy new driveshaft interfered with the OEM stainless steel exhaust heat reflector. Unwilling to do away with it (especially given the increased heat sensitivity of a carbon fiber driveshaft over the OEM steel unit) Bob carefully trimmed and massaged the heat shield and reinstalled it, doing such fine work that it is virtually impossible to spot the modification.

With the driveshaft fiasco out of the way, it was smooth sailing from there.

Nobody makes a performance after-market replacement for the rear lower suspension arms, so we settled for some standard pattern parts from Moog. We attached them to the subframe with an ISR eccentric lockout kit. The OEM setup uses bolts set in eccentric washers that are twisted in place to set the rear camber and toe adjustment. These fasteners are prone to slipping under heavy load, thus ruining the alignment. We could now set camber and toe with our adjustable rear arms, rendering the eccentrics redundant. The lockout kit eliminates them for a stronger installation.

We also replaced the rest of the hardware. OEM hardware is expensive and you can’t actually buy all of it individually which is an annoying, though seemingly standard practice for Hyundai.

Happily, BelMetric.com came to our rescue with top-quality automotive grade 10.9 fine-thread metric bolts with through-hardened washers and extra-stout nylock nuts. This hardware is easily as strong and corrosion resistant as the OEM parts and more resistant to loosening over time due to the added security of the lock-nuts.

And with that, Project Hoondy was back on the ground once more. It wasn’t a quick process, or cheap. How not cheap? Well...

- Sedan Rear Subframe: $280 shipped

- Two tubes of 3M Window Weld: $40 shipped

- 4.181 Genesis Coupe Differential: $250 shipped

- ARP ring gear bolts: $85 shipped

- Driveshaft Shop CF driveshaft: $1215 shipped

- InsaneShafts rear axle shafts: $700 shipped

- ISR rear control arms: $705 shipped

- ISR eccentric lock-out kit: $80 shipped

- Moog rear lower control arms: $230 shipped

- Grade 10.9 hardware: $60 shipped

- Whiteline rear swaybar kit: $185 shipped

- Whiteline adjustable rear swaybar end links: $115 shipped

- Expert labor from After Hours: $997.50

A grand total of $4942.50! Ouch.

Granted, the cost of parts was spread out over the course of a year, but still, that hurts no matter how you slice it. We’d argue that the car was due for replacement rear control arms anyway, which would have cost somewhere between 700 and 900 dollars in OEM parts and shop time. Even taking that out of the equation, that leaves us with four grand worth of added cost that was purely optional on our part.

Needless to say, expectations were high for just what a difference all this mechanical love would make to the car’s driving dynamics. Tune in next week to get the dirt on our results here on Project Hoondy!