Many months ago, I wrote about how I probably need my head checked for buying a Touareg V10. Granted, I bought it for cheap already knowing what level of work would be needed to make it right again.

Well, I ordered a set of camshafts from a company in Canada, and FedEx lost them... It’s taken a lot of time to go through their claims system to try and get it resolved, and they only paid about 10% of what I actually paid for the cams. So, eventually I’ll have to try my hand at small claims.

I got tired of waiting to get my money back to buy again, so I went ahead and ordered another set, they’ve now shown up and I’m starting the work.

The whole drivetrain is out. The engine, transmission, transfer case, front axle, front prop shaft, steering rack, front sub frame and most of the front suspension and brakes come down as one assembly. The two 60 pin connectors (one on each ECU, the ECUs—yes, plural—also have a second 94 pin connector that stays with the body side) come off the two engine computers and the vast majority of the wiring harness for the engine comes out with it, a few connectors also had to be undone at the ebox on the driver side next to the wiper motor. The two glow plug wiring harnesses are wired into the body harness and get disconnected separately. MAF wiring also stays with the body, a coolant temp, AC pressure sensor and some kind of valve or sensor on the steering rack had to be unplugged as well. Overall, undoing the wiring was the easy part.

Undo a few vacuum hoses, a number of coolant hoses to the radiator, and auxiliary radiator and the heater core have to be undone, and the ones at the front/lower section of the truck aren’t the easiest to undo. AC had to be discharged and a couple hoses disconnected. Trans cooler lines too, shift linkage at the transmission. Rear exhaust removed, rear driveshaft too.

All told, with me taking my time, it took about 10 hours just to drop the assembly.

And now with it on the ground, time to get into the reason why I removed it.

First, we’ll start with what a normal cam valve lobe is supposed to look like on a VW pumpe duse TDI engine. Notice the chamfer all the way around the edges of the lobe. When these start to wear, that small chamfer will be the first thing you notice as being gone at the apex of the lobe, and the edges mushroom over a little and become a sharp edge.

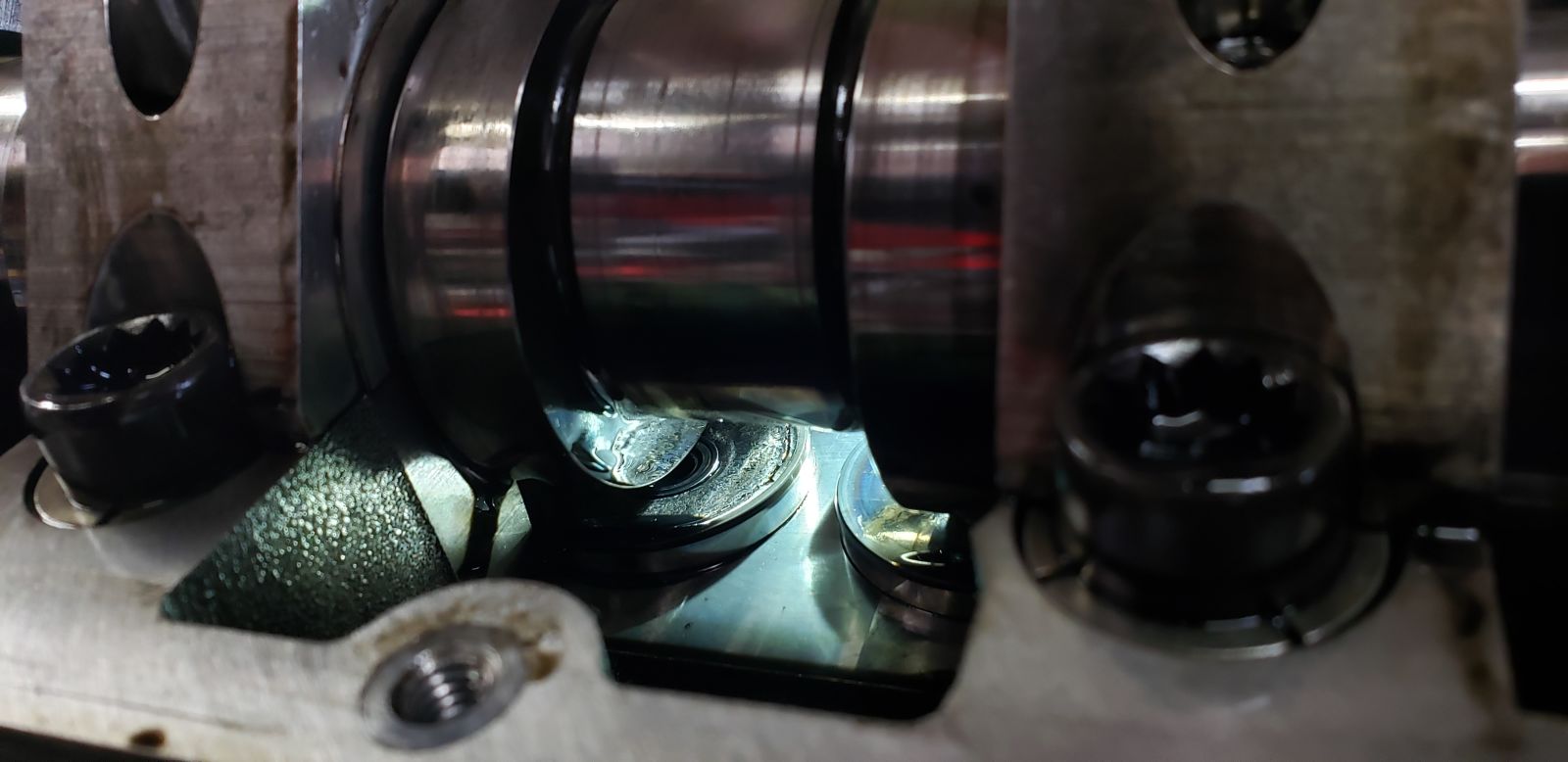

What one of the lobes on bank 2 looks like:

I’ve seen many worn PD cam lobes before. It’s an unfortunate engineering failure on VW’s part on this particular style TDI engine. The 4 cylinders we got here in the U.S. from 2004-2006 are just as prone to this sort of thing. Unfortunately, the big bad, expensive V10 was not spared from this engineering oversight. This one lobe just might be the most worn/flattest I’ve ever seen in a PD, though. And I’ve seen numerous 4 cylinders that have worn holes into the lifters... Speaking of, here’s a photo of the corresponding lifter underneath:

Nice, large dish worn into it and a hole. The lifter next to it? Perfectly flat.

The cool thing about this engine, which also makes valvetrain work expensive and time consuming? The cams are gear driven on the V10. The 4 cylinder diesels all use a timing belt. In fact, there’s not a belt anywhere on these V10s, not even for accessories. Everything is gear driven or is coupled to another accessory that is gear driven.

Here’s bank 2's cam, lifters, cam caps and gears on the bench:

You can see one of the lifters on the left part of the screen was starting to dish out and wear as well, as was its corresponding cam lobe.

While I’m in the engine this deep, knowing what I do about PD TDIs, might as well do injector seals too while I’m in it this far:

The other issue it had is bank 2's turbo’s external rod linkage corroded to the point of preventing the full range of movement of that turbo’s actuator/control module, and thus vane mechanism. This actually caused the truck to immediately set a “turbo control module defective” upon turning the key on. This is because the control module does a check every time it’s keyed on, it goes to its min and max positions real quick to make sure everything is OK. And when the module is physically prevent from going through its full range of motion, it sets that code.

This leads people to believe the turbo control module is, well, defective. Because that’s what the code said, right? Well, before I removed the engine, I did a test. I popped the linkage off bank 2's turbo control module (the one that was setting the code) and attempted to see if I could move that turbo’s vane mechanism by hand, and when I realized it was physically impossible to do at the angle it was mounted at, I decided to key it on, clear the codes, key it on and off a couple more times, allowing the turbo modules to go through their self checks of min and max position each time, and then recheck for codes. Guess what? The turbo control module defective code didn’t come back so long as the linkage was removed from the control module, thus allowing the module to be able to move through its full range of motion.

So, while it’s out and I confirmed the vane mechanism internally in the turbo moves freely, I removed both linkages, sanded the rust off each arm and used a small “grinding stone” in my dremel kit (the stuff is softer than the steel the rods are made of, so minimal removal of metal will happen, but works great to remove the corrosion) to remove the corrosion from inside the arms. Used some high temp synthetic caliper grease slathered all over inside those pivot points, reassembled, and then slathered some more on the outside in an effort to prevent the corrosion from happening again.

I think every oil change I will peek up there and make sure the grease still looks OK, and reapply as needed. I’m curious to see how long the stock turbos can go, and prove people wrong that these are not actually fragile junk. It’s just a small amount of preventative work that should in theory stave off the dreaded turbo control module defective codes once you understand the most common way that code sets is merely an external linkage corrosion issue.

And with that, back at it. I have to install the new cam on this bank, and then tear down bank 2 and do the same. Hoping that by the end of the week I’ll be driving it, get all the readiness monitors to set, go get it titled and plated in my name and enjoy.