Meet Tiger. Tiger is a 1999 Epiphone Dot, basically an imitation of a Gibson ES-335. I inherited Tiger about 10 years ago. Let me tell you right off the bat; Tiger is a cheap guitar. When I say cheap, I mean the quality of the components that Epiphone uses to make guitars like Tiger are lower and less robust than, say it’s Gibson lookalike. It has a plastic nut, electronics and tuning heads made in low cost factories, and made with mass production techniques that require wider tolerances for quality control. From the factory it’s an ok guitar to learn on and to play in your studio. Some people even gig with them but push ‘em through the rigours of even a weekly dad-rock session and their limits are usually noticed by an intermediate player.

Tiger has some redeeming qualities. He was built in the mid ‘90’s, at a time when Epiphone built this model in Korea, which some say produced better quality instruments than its contemporary Chinese or Indonesian factories. During the ‘90’s, the manufacturers were chasing costs out of their instruments, which meant Japanese factories gave way to cheaper labour from Korea, then Indonesia then China. Tiger has a very nice flame maple top (hence the nickname) which goes so well with the vintage sunburst finish. The Epiphone probucker pickups installed are nicely voiced and maybe even on par with the Gibson 57 classics in my SG, as far as tone goes.

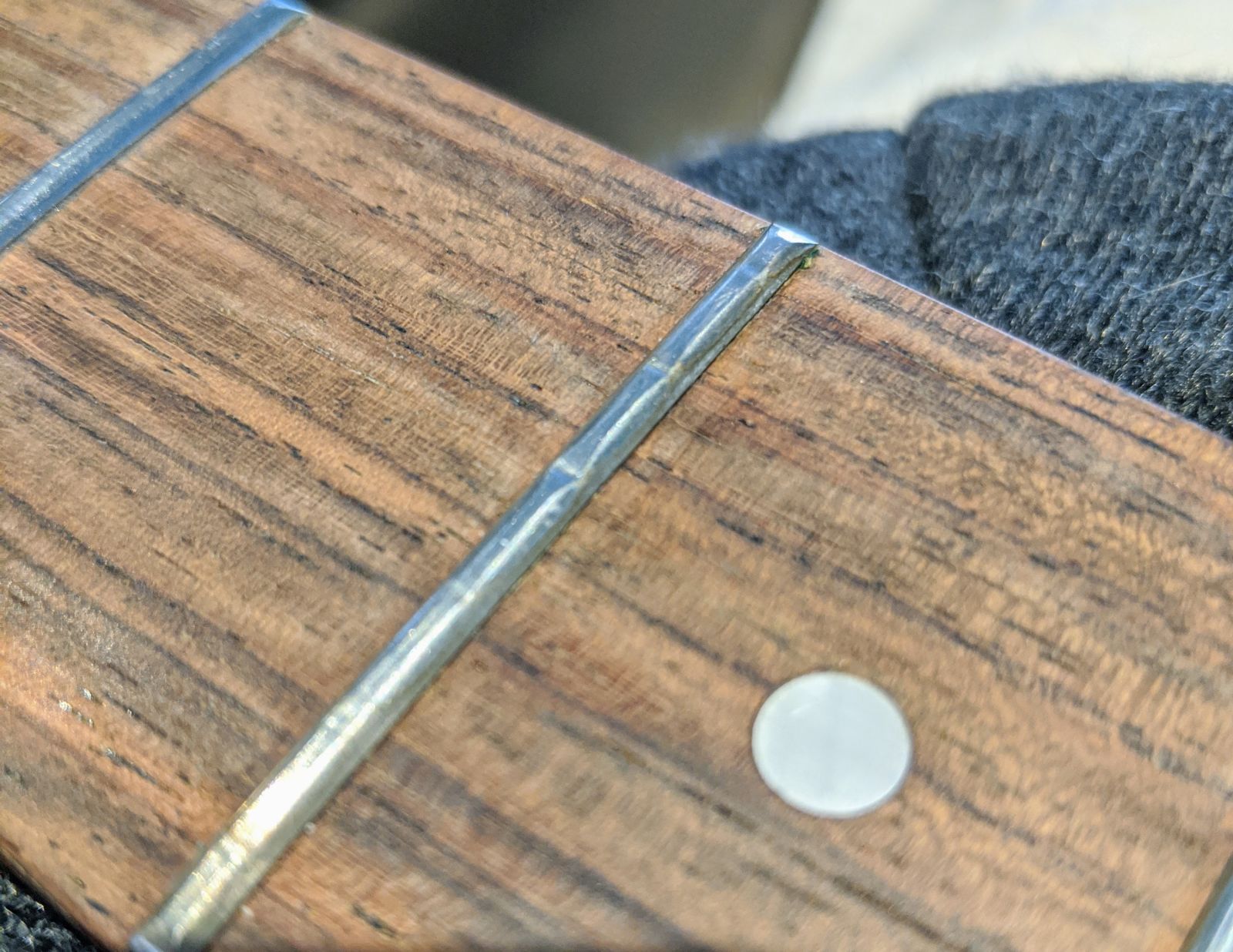

Tiger has been abused. It looks like someone dropped him on his fretboard, seriously denting some frets.

Because of this, Tiger has been either in a case or hanging on a wall for the last 10 years. Barely played, neglected. Call me a ableist but I’ve got other options at my disposal.

Now, for an expensive guitar, dented or worn frets would mean a trip to the guitar tech for a fret leveling or a spot replacement fret. It’s an easy decision to spend $50 to possibly $300 on a thousand dollar guitar but when the guitar costs $400, it begs the question; cut my losses and buy another less expensive guitar? You’ll find lots of those guitars hanging on the wall never to be played again or sold on Craigslist, now someone else’s problem.

Tiger is in luck. I know guitars. I can fix him. In fact I enjoy it. It’s my zen time. It’s the same relaxation I get from tuning carbs or bleeding brakes or doing guitar setups. So I spent most of the day getting this guitar back into playable nick, even better than the factory spec for fret level-ness.

First off, I adjusted the truss rod until the neck was perfectly straight (guitar necks need to have a slight bow to allow the strings to vibrate). Then I masked off anything I didn’t want to damage while I’m sanding and filing.

Once everything is masked off, I use a thread rocker tool to find the high spots and mark them with red sharpie. Everywhere else gets black sharpie.

Then I used my 14” sanding beam and went to town on the frets with 320 grit. The goal is to get every fret top perfectly level will all the others. You don’t want to take off more than you need to, so you take off all the red and continue just enough to kiss all the black sharpie evenly with the sanding beam.

Then I use a file to reshape the crown on each fret. Then 400, 600, extra fine steel wool and finally a 4000 sponge. After that I oiled the dry fretboard wood. Turned out pretty good.

One other thing I fixed was the bridge saddles that were back assward. The tapered part of the saddle should face the tail stock or else you can get weird twangs when you don’t want them.

Bonus shot of my extraneous DNA matter on that bridge. I also gave those bridge saddles some deburring love with the diamond files. One of those things overlooked at the factory for the sake of saving time.

Then Tiger got a new set of NYXL 10-48 strings, neck relief adjusted to .012”, string action set and bridge saddles adjusted to set the correct intonation.

Five hours later, Tiger’s got a new lease on life. Action is low with no ‘choking’ exhibited like you see on older set-neck guitars. Would someone spend $200 at a guitar shop to fix a $400 dollar guitar? How about shop rates to swap out struts on your E36? Hard choice, unless you can do the work yourself. It’s the same thing as working on your own vehicle; you can enjoy your own zen moments filing or sanding or wrenching while you can keep mutts like Tiger or your favourite beater from being torn down for parts.

E:Repost for embiggin?