I’ve owned a B5 chassis Audi for the last 12 years or so - sedan and wagon flavored A4s, and most recently an S4 wagon. Through this ownership period, I’ve consulted lots of resources online for help fixing various problems, and while there are lots and lots of people replacing valve cover gaskets, CV joints, and coil packs, there are OTHER people who do work on their cars when they’re NOT BROKEN. wat. I desired very much to join this second group, who voluntarily make their cars less reliable in the pursuit of additional ‘performance’, or maybe just for message board and blog material (‘WTF ran 35psi boost and broke stuff LOL typical Audi). However, my car has never reeeeeeally been reliable enough to provide me a good ‘baseline’ point from which to begin modifications, but I figured a 17 year old car with 189,000 miles was a really nice platform from which to begin. Plus, I can just fix all the crap that’s broken along the way, right? right.

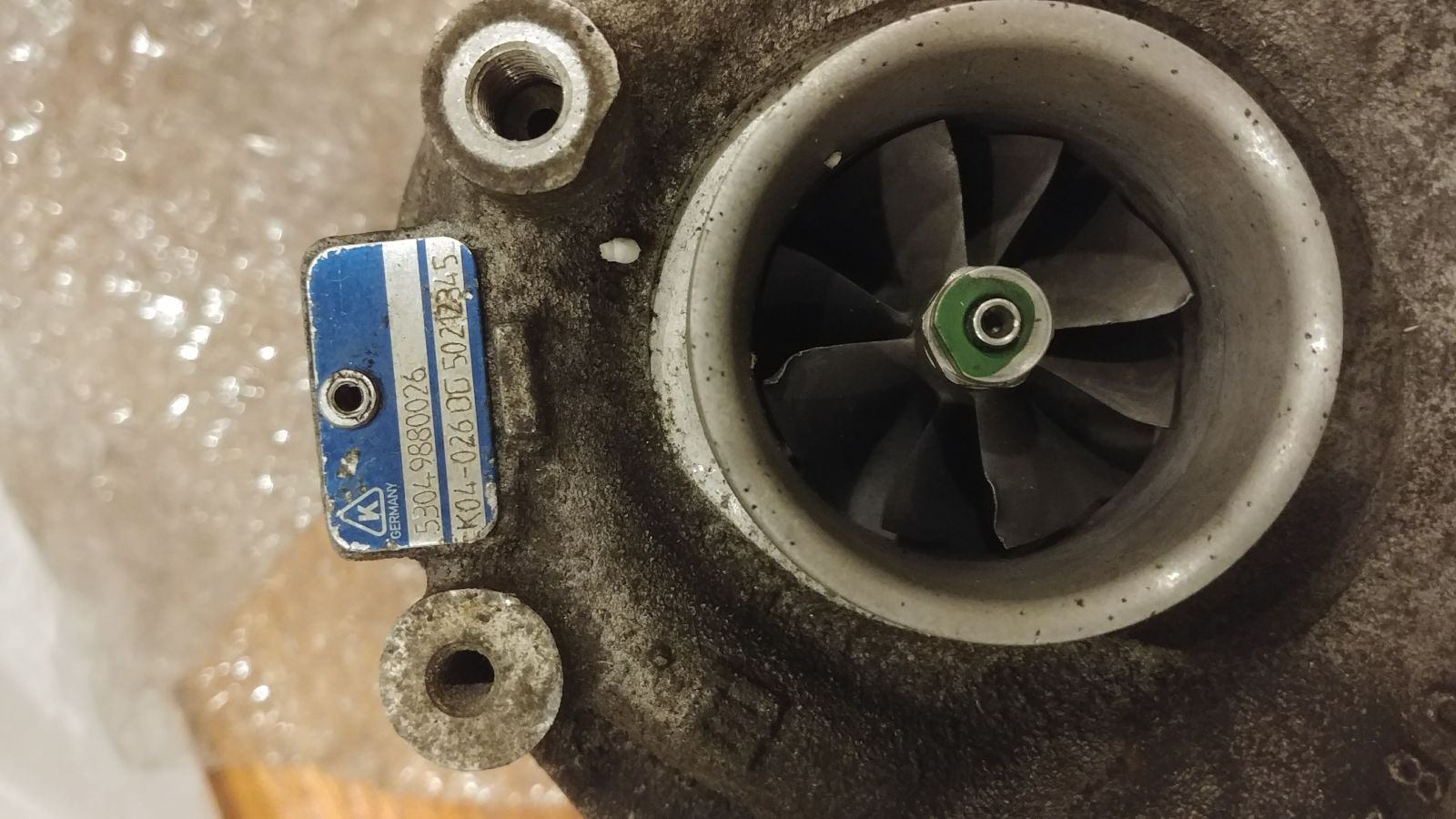

Anyway, I decided to go the baby Stage 3 route - K04 turbos and a tune with a relatively long track record from 034 Motorsports. I found turbos and a clutch from a fellow forum member - STOKE LEVEL HIGH - and immediately had to replace the CHRAs for both turbos since they looked like dis:

STOKE LEVEL: mediumz

FAITH IN INTERNET: shaken

This is the type of project where I am not allowing logic to influence the sequence of events - I’m going to end up with a rusty, ancient, mom-mobile super wagon rocket belching oil or I am going to be VERY UPSET.

Still unsure on the clutch - it’s an RS4 clutch that allegedly has 10k miles on it, but you know, so did the turbos so I’m still on the fence about that. Also have a dual mass flywheel that can get resurfaced once (I think?) but also haven’t solved that problem yet. Have other hurdles to get past, anyway.

These major pieces assembled pushed me over some sort of event horizon and I cobbled together most of the rest of what I needed - injectors/adapters, fuel pump, lots of hoses, some bolts, I dunno, other stuff. Also figured I can do some maintenance WHILE I’M IN THERE so the timing belt/water pump and related items will go in too. Hoping to address some oil leaks but not really expecting to be successful.

So a couple weeks ago, up she went on jackstands in my garage, and I started pulling stuff off in order to pull the engine and transmission. I’ve been using a couple of really thorough writeups that were put together by folks much more detail-oriented and competent than me - this one from a member on QuattroWorld (BingS4) , another checklist from somewhere that escapes me now, and this very enjoyable summary of this process from SUV on QW, part of the inspiration both for the project and to try and document it to some degree.

Over the course of the last two weeks, I managed to get to this point:

A quick insight, or two - briefly because this process has been done a lot in the intervening years. Made a big mistake not removing the top AND bottom bolts from the transmission mounts before attempting to remove the engine. It really didn’t seem like a big deal, and the top bolt was a little tough to access, and the directions sorta said it was just to get a little more clearance when the engine comes out so I figured: I’ll just deal with a little less clearance.

No, I won’t. I ended up cutting the head off the bolt (with a sawzall! somewhere David Tracy found himself wearing a wry smile without knowing why) once the engine was on the hoist and about 6" forward in the bay because I couldn’t remove the bolt with a wrench as it just spun the mount that was no longer attached to the subframe. And that extra clearance was only ‘extra’ in the sense that oxygen is an ‘extra’ gas in air. Anyway, lesson learned. My engine hoist’s piston wasn’t what you would call full of oil either, so its pick height was limited. I do this to myself.

I have a couple mild panic attacks each day that I work on it - YOU CAN’T GET THIS BACK TOGETHER - and then I calm down some and think about each achievable step strung together. I do have time to do this project, although the early snow has me questioning the logic of taking the only AWD out of service and taking up a garage bay. I have made a promise that I won’t use the wrong tool in the interest of time (only broken a few times) and that I’ll do thing ‘correctly’ if possible. I know myself well enough not to set goals I will immediately break.

I haven’t broken anything big - one small coolant hardline that I probably compromised in some earlier half-assed repair, some bolts that likely hadn’t ever been touched, and stuff that’s getting replaced anyway, like the serpentine belt and tensioner.

Anyway, the next step is the timing belt and related parts, if only because I rented tools to help with that (cam lock bar, some other fancy German bits I’m sure) and it has to go back within a week. I’ve been preparing by watching Justin Ballou videos on YouTube. I GOT THIS.

Hope it’s interesting to someone, and if not then I’ll just cry into a bucket that already contains a mixture of coolant, oil, brake and washer fluid.