Update: I was finally able to get back to this project this past weekend. (Why does life always get in the way of the projects I actually want to do?) As was suggested by Rusty and JawzX2, the tapped holes were nowhere near clean. Embarrassingly so. After copious amounts of chlorine-containing brake cleaner and many cotton swabs, I think they’re clean enough now that threadlocker would work a lot better. With that said, I also followed advice from just-a-scratch and called the local Fastenal store so I could talk to a human. They can sell me the drive screws by the each rather than a box of 5000. I was able to order 30 of them (more than I need, but adds a buffer) for less than $8. I should have called them in the first place! I won’t have them until Monday, but then I can make an educated decision about which fastener I feel better about. Thanks everyone for your suggestions on this. Hopefully I will be able to update again in the middle of next week.

[Original post] I am working to reassemble the engine for our Suzuki Grand Vitara after replacing the timing chains, gears, and chain tensioners. These engines (the Suzuki H25a, if you’re interested) are notorious for sludge build up, leading to chain tensioner failure and eventual destruction of the engine. While I have the engine out and partially disassembled, I’ve done quite a bit of cleaning to eliminate as much of the sludge as I could. That includes disassembling, cleaning, and reassembling the valve covers.

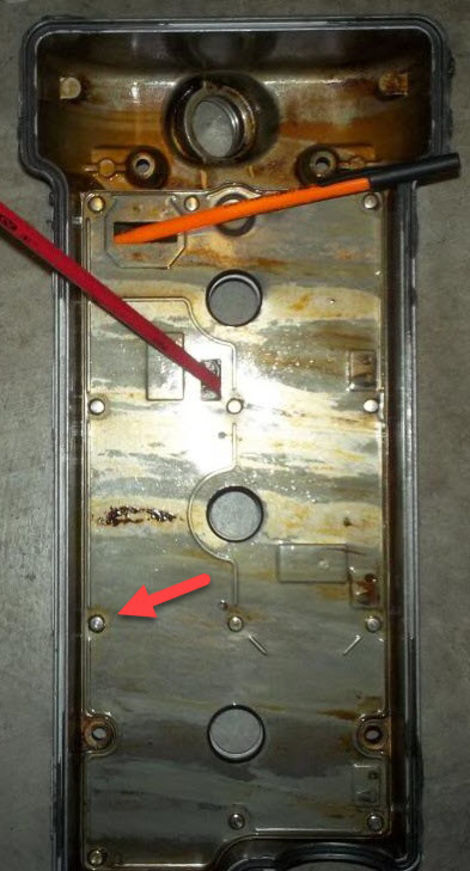

The covers have an internal baffle that is supposed to keep the PCV from sucking oil out into the intake manifold. The baffles are held in by what I believe are a series of drive screws. One is indicated by the arrow in the picture. Because the covers were so nasty under the baffles, I was concerned that having a shop boil them out would leave me wondering if anything was still underneath. So I drilled the top of the drive screws to remove the baffles and proceeded with the cleaning. They were disgusting underneath. I truly don’t believe any amount of time in the parts washer would have gotten them completely clean, especially given the maze of walls under the baffle plates. They weren’t draining properly, exacerbating the very problem they were supposed to prevent.

I thought I’d reattach them using 6 mm machine screws, along with some red threadlocker. All the instructions on the threadlocker liquid say it will take significant heat to remove a bolt held in by the red stuff. I must have done something wrong, because it took very little effort (and no heat at all) to remove them after the 24 hour cure time. I even used their surface prep spray since the valve covers are cast aluminum and the bolts were stainless steel.

So that gets me back to the drive screws. (Also referred to as u-drive screws or type u drive screws.) The machinists out there (and other folks smarter than me) will already know this, but a drive screw is essentially a self-threading screw that you hammer into a pre-drilled pilot hole like a nail. As an interference fit, they have to be drilled out to remove and are considered a permanent fastener. My problem is this: I drilled and tapped the holes for 6 mm machine screws. Now that plan has failed and I need to use drive screws. From what I can see, the largest ones normally available are #14 drive screws, but the specified pilot hole for those is 0.221". The 6 mm holes already in place are 0.236", so I don’t know if the #14 drive screws would hold properly. I have seen reference to 5/16" drive screws, but the pilot hole size jumps significantly - up to 0.295". I’m not sure I have room for that size pilot hole without risking splitting the boss that they would be driven into.

TL;DR: Would the #14 drive screws work? And where in the world do you buy small quantities of these things? The only suppliers I have been able to find want to sell them in boxes of 1000 and up. I only need 24 of them! Is there a different/better fastener I could use?

Sorry for the long post, but in this case the details kinda matter. Any advice will be greatly appreciated.